Inflated bubble wrap pouches making machine

- Previous: Automatic Air Bubble Film Bag Machine

- Next: Air Column Box Making Machine

Machine Introduction

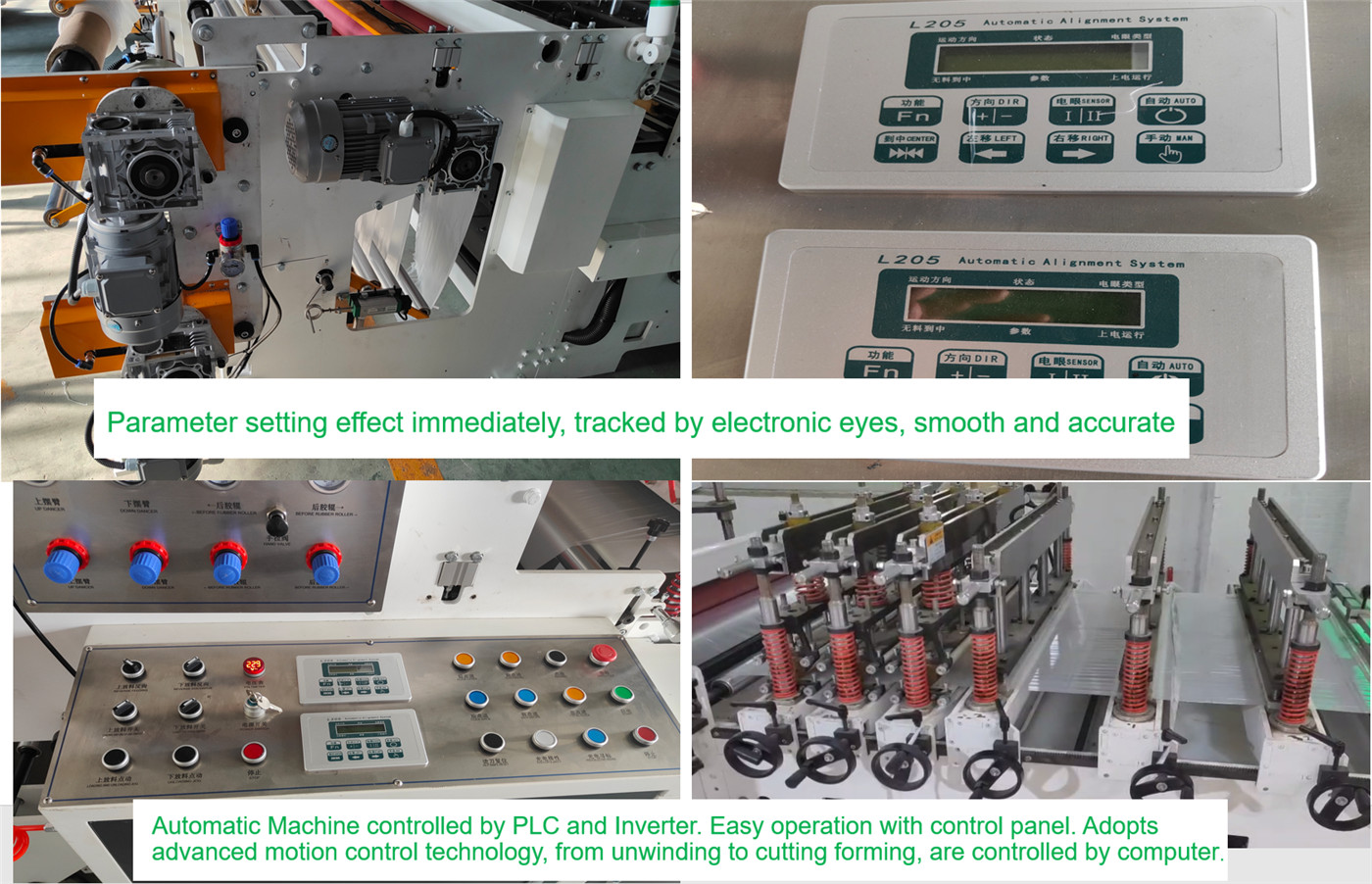

Inflatable bag making machine is a fully automatic bag making system from material folding to heating and cutting. Using advanced motion control technology, from unwinding to cutting and forming are all controlled by computer. The result of each production is a stylish, attractive bag that is strong, reliable and easy to handle. The inflatable airbag packaging reel machine adopts a reasonable and compact mechanical design, which limits the operating noise. Microcomputer control system, liquid crystal display, provide easy-to-understand operation instructions in Chinese and English. It is an ideal production equipment for bubble bags or kraft paper bubble film.

main features

1. The linear structure of the airbag winding machine is simple and easy to install and operate.

2. The inflatable packaging bag production line adopts advanced brand components such as pneumatic parts, electrical systems, and operating parts. We source all machine parts from the best machine supply chain area in China, make sure the machines are stable, and almost zero after-sales service is required.

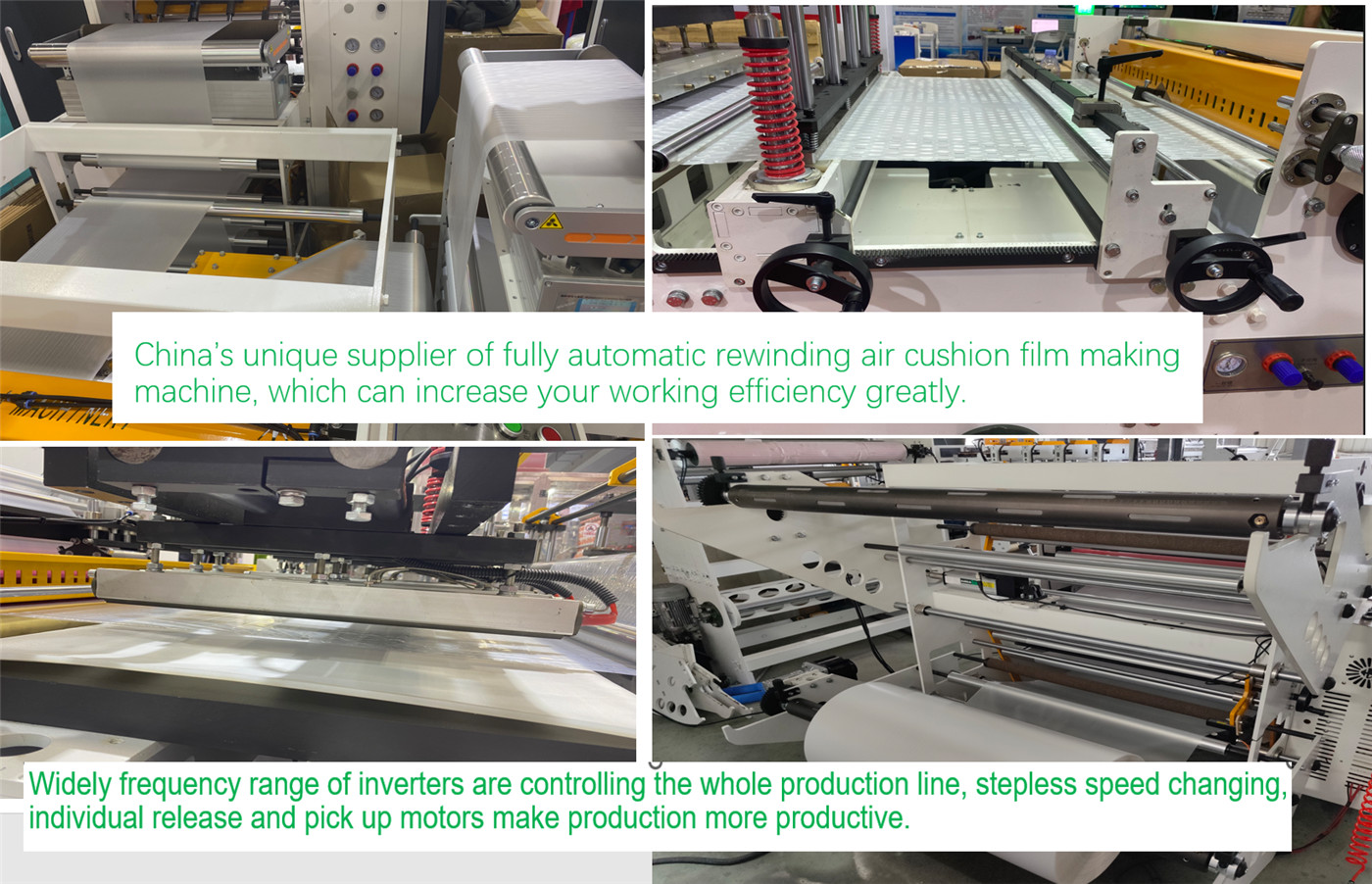

3. The airbag packaging machine has a high degree of automation and intelligence, and is equipped with a domestic unique automatic winding system.

4. The air cushion bag making machine adopts advanced motion control technology, from unwinding to slitting and forming are all controlled by computer.

5. The fully automatic machine is controlled by PLC and frequency converter, the control panel is simple and easy to operate.

6. The parameter setting takes effect immediately, and the electronic eye tracking ensures smooth and accurate bag making.

Application& related items

Our Factory