Air bubble cushion film Making Machine

Machine introduction

Introducing our state-of-the-art biodegradable bubble wrap packaging recycling green bubble wrap machine, designed for eco-conscious companies looking to reduce their environmental impact without sacrificing packaging quality.

This innovative plastic inflatable bubble bag making machine is capable of sealing the air path, film sides and crosscut in a single in-line process. It is specially designed for use with PE coextrusion packaging film, allowing you to package a variety of products including electronics, shredded materials and more.

Our machine also has the function of making single-layer PE bubble film, which ensures power saving, high efficiency and easy operation. By integrating mechatronic equipment, your packaging process becomes seamless and easy. The fully automatic plastic air bubble film bag making machine is ideal for companies that need to produce high quality air bubble film quickly and efficiently.

Our machines are designed to operate at speeds suitable for large-scale production environments, while delivering exceptional bubble film quality. Here are some highlights of our innovative bubble wrap machines:

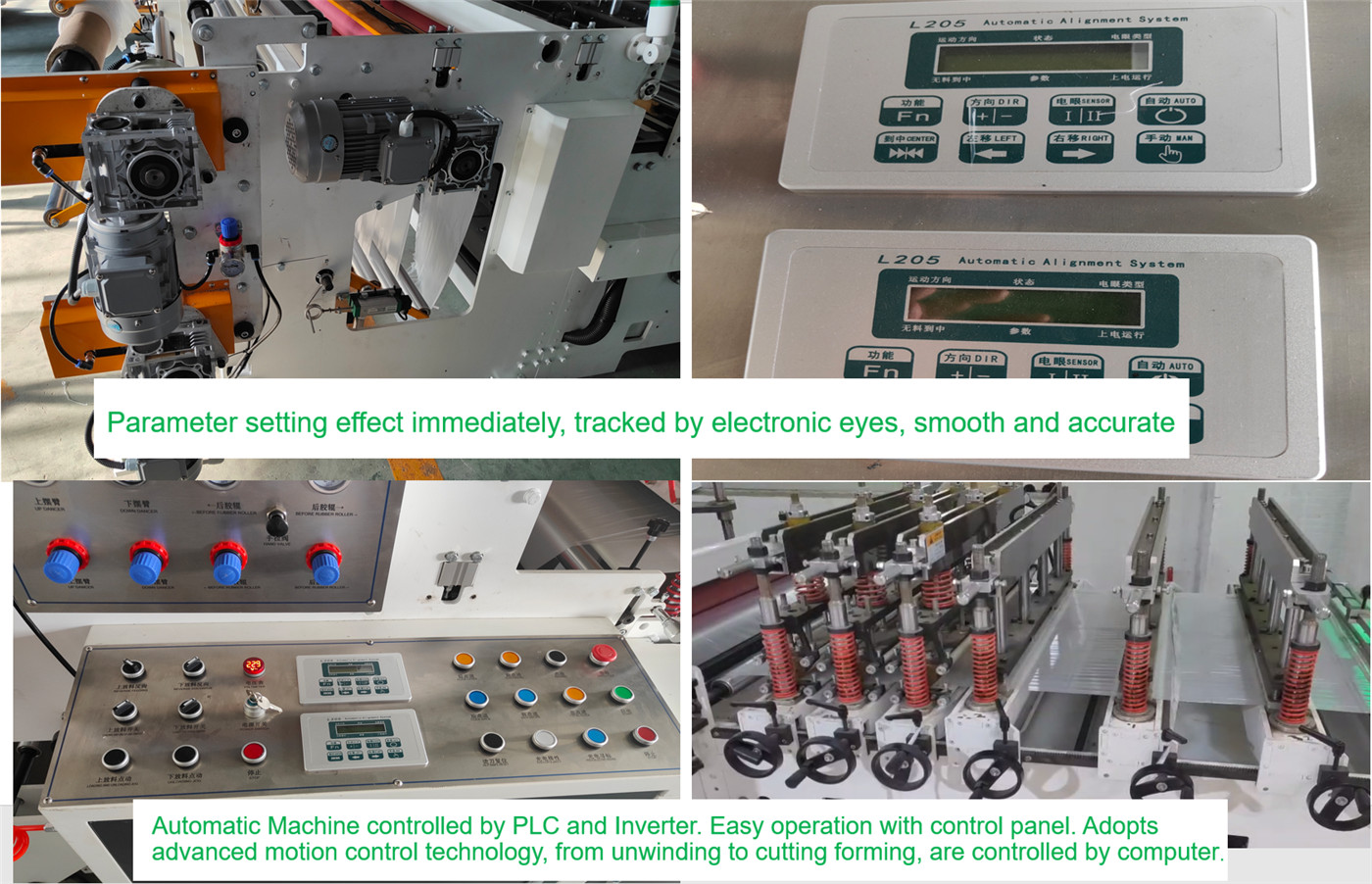

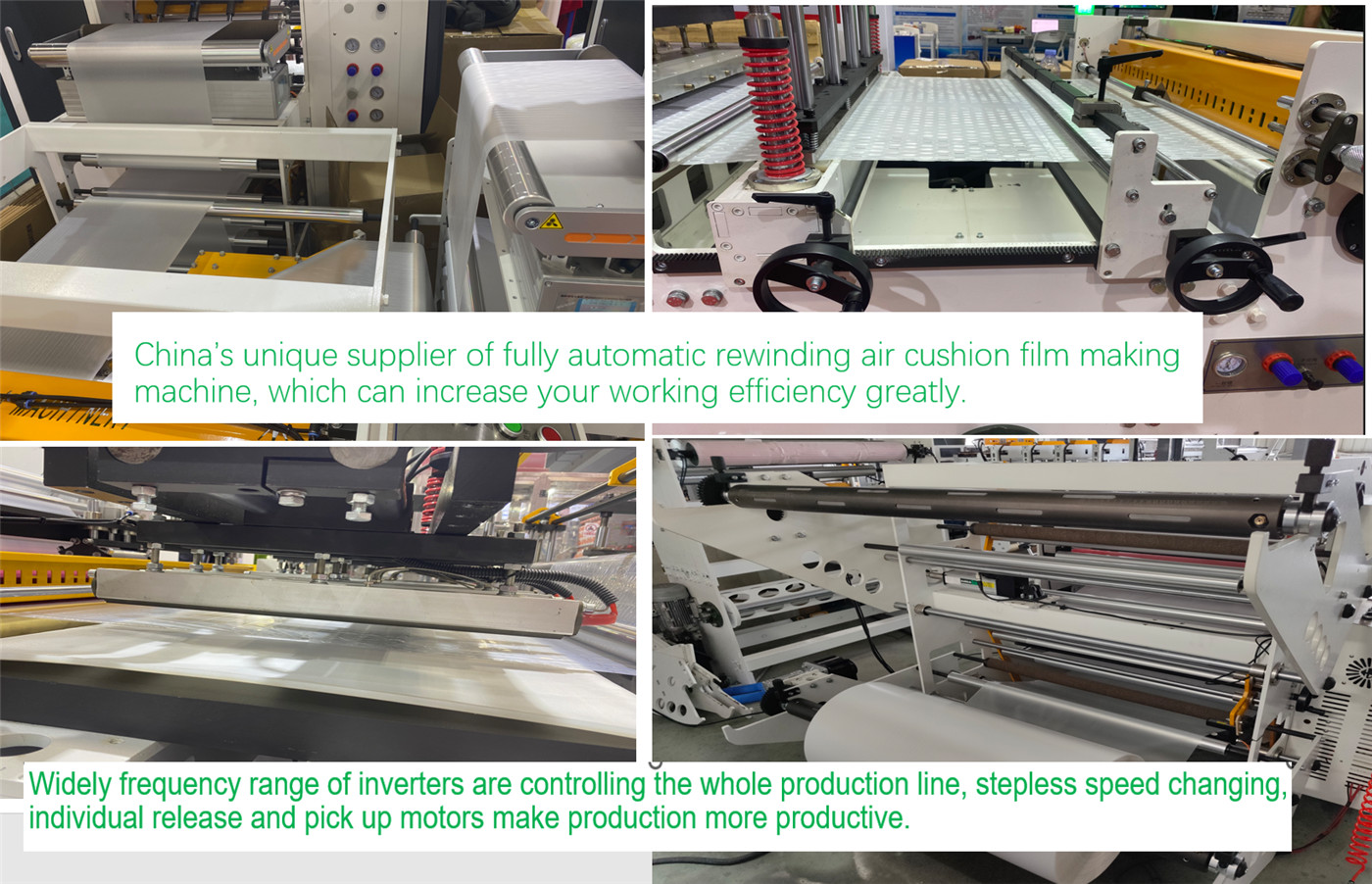

1. Inverter with wide frequency range for complete line control. Continuously variable speed, independent pay-off and pick-up motors improve production efficiency.

2. Our high-speed inflatable film bubble cushion airbag packaging machine adopts air shafts in the winding and unwinding parts, which is convenient for loading and unloading products.

3. Our machines have functions such as automatic homing, automatic alarm and automatic stop, designed to provide you with the best results while minimizing downtime.

4. The air bubble film side sealing bag making machine is equipped with a fully automatic EPC device in the unwinding part to ensure that the film is uniform.

5. The winding and unwinding part is equipped with a high-function potential sensor to ensure continuous film feeding and stable unwinding.

6. Our air bubble film bag making machine is designed with the grating device of motor deceleration and brake integrated machine, which eliminates the belt chain and noise. This feature provides excellent stability and precision.

7. The factory directly sells the fully automatic bubble cushion protective film making machine, and the unwinding place is equipped with photoelectric eye EPC to make the film flatter and tighter.

8. Although our machine may not be the oldest, it is the most upgraded model in China. Many famous packaging companies are upgrading their air column cushioning bag production lines with our machines. Upgrade to our biodegradable bubble wrap packaging recycling green bubble wrap machine today and join the environmentally conscious sustainable packaging movement.

Application& related items

Our Factory