Automatic Air Bubble Bag Making Machine

Air Void Fill Cushion Machine Introduction

Inflatable cushion bag making machine, air cushion bag making machine, biodegradable bubble bag making machine are all advanced equipment for producing high-quality packaging materials. These machines are fully automatic bag making machines, starting from material folding, heating and cutting.

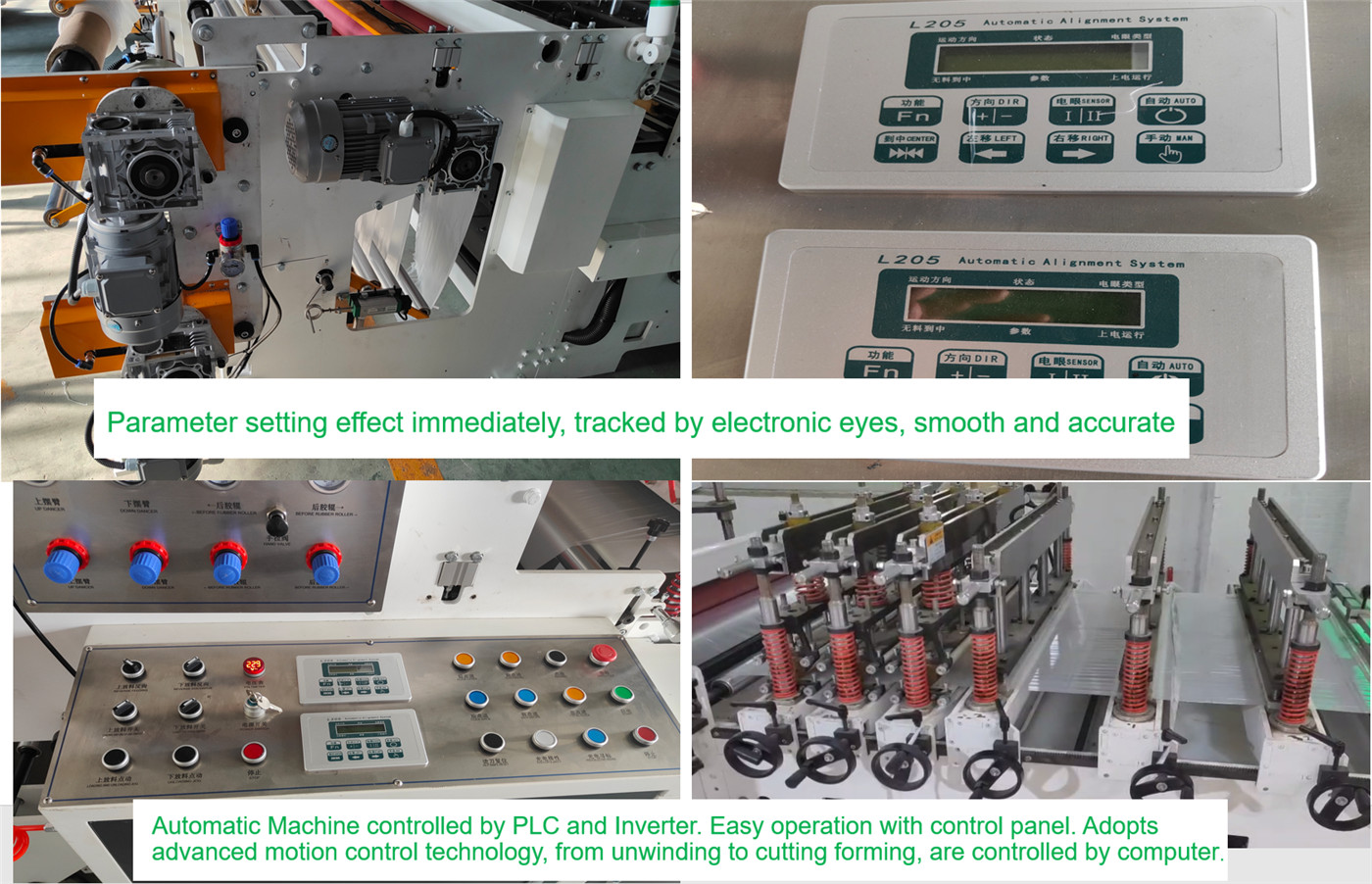

Using advanced motion control technology, the machine is operated by computer to ensure that each bag produced is smooth, beautiful, firm and reliable. The operation of the machine is simple and easy to understand, and the LCD screen provides operating instructions in Chinese and English.

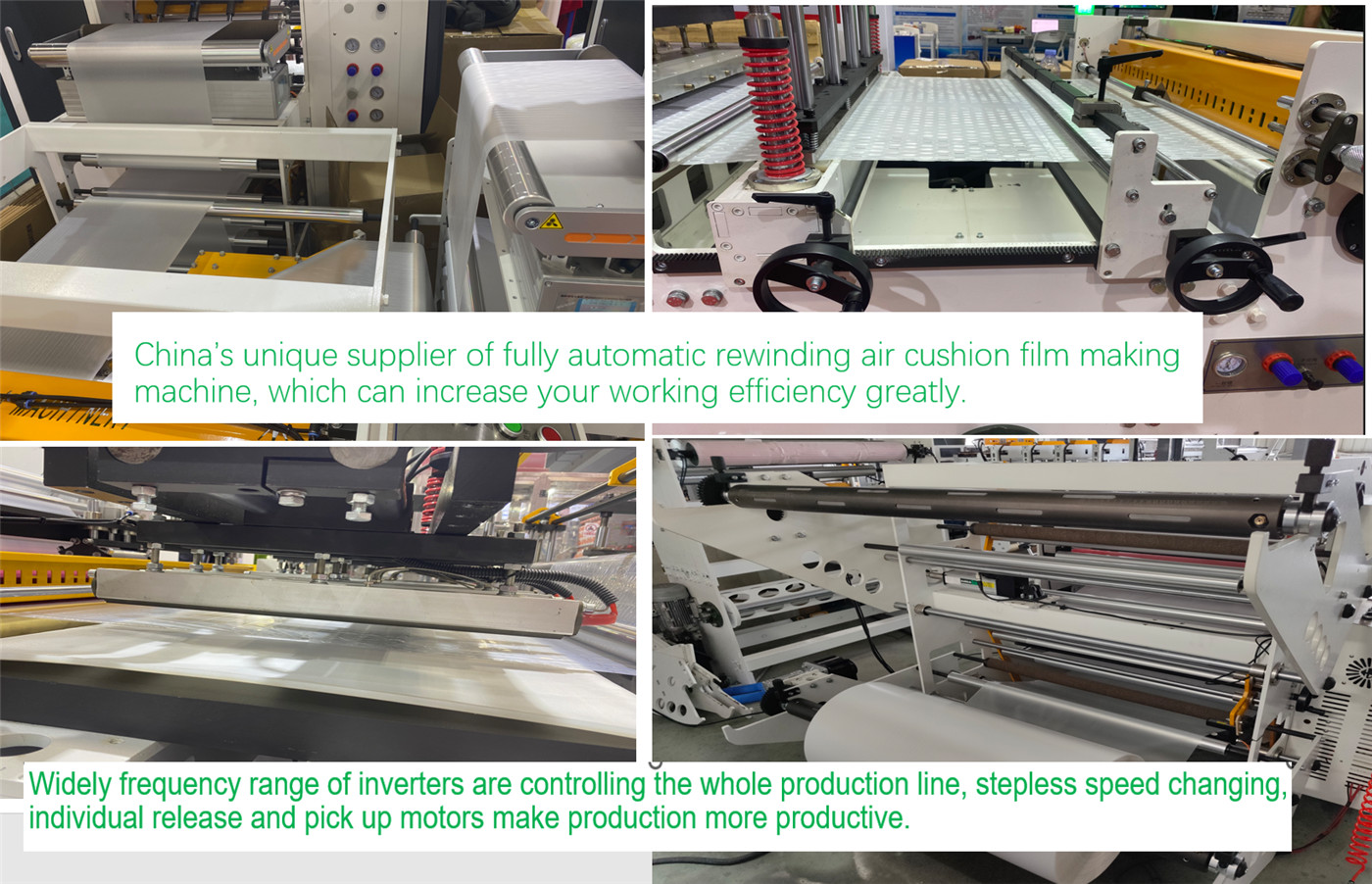

In addition, these machines have a reasonably compact mechanical structure and generate low noise. Sealed Plastic Air Void Fill Shipping bag machine and the Airbags film rolling machine is ideal for the production of bubble bags and kraft paper bubble wrapping.

Overall, these machines are efficient, reliable and reduce packaging waste as they produce biodegradable materials. They are the equipment of choice for businesses looking to produce high quality cushioning void filler and packaging materials.

Main Features

1. The air cushion packaging bag making machine adopts a simple linear structure, which is easy to install and operate.

2. The pneumatic and electric systems and other parts of our airtight hole filling film rolling machine adopt high-quality brand parts, which come from the best machine supply chain in China. This ensures a high degree of stability with virtually zero post-sale support requirements for our customers.

3. Our air hole filling protection manufacturing machine has a high degree of automation and intelligent operation. We are the only automatic rewind supplier of this machine in China.

4. The gap filling protective packaging material manufacturing machine adopts advanced motion control technology to precisely control the process from unwinding to cutting and forming, all controlled by computer.

5. Both the packaging air cushion pillow film rolling machine and the packaging air bubble rolling machine are controlled by PLC and frequency converter, with an easy-to-use control panel.

6. Our machines have instant parameter setting function, precisely tracked by electronic eyes to ensure smooth and accurate production process.

Application& related items

Our Factory