Air cushion film rolls making machine

Machine introduction

The air cushion packaging machine is an advanced and efficient way for enterprises to produce inflatable bags, hollow cushion bags and inflatable bubble films. The machine is equipped with cutting-edge technology for precise and fast production, making it ideal for large-scale production environments.

This machine can produce air-cushion film rolls made of PE co-extruded packaging film, which is suitable for packaging various items, including electronic products, broken products, bags, etc. The air bag produced by the machine provides a delicate and beautiful packaging solution, which can ensure the safety of the product during transportation.

Here are some key features and benefits of our air cushion packaging machines:

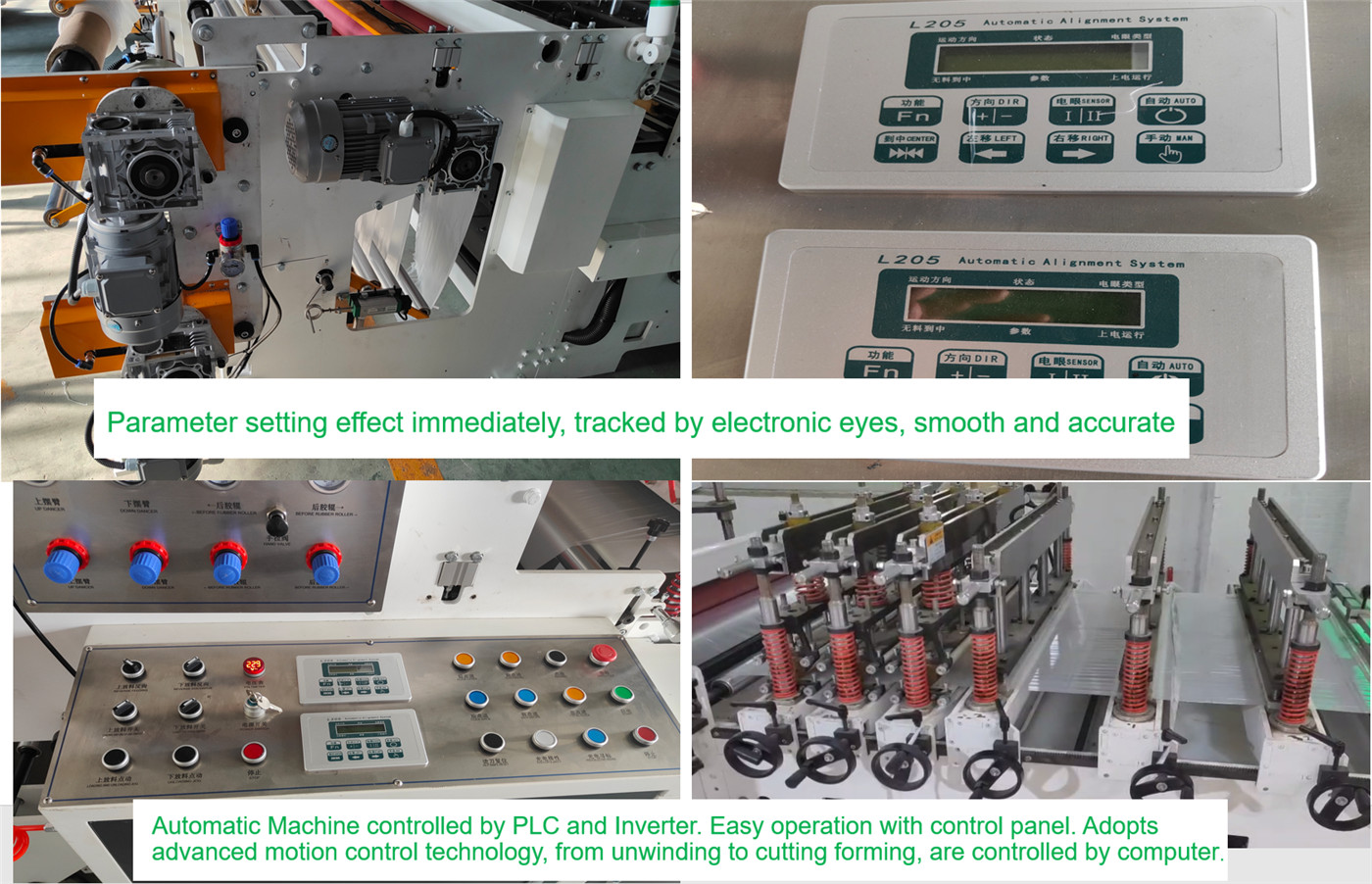

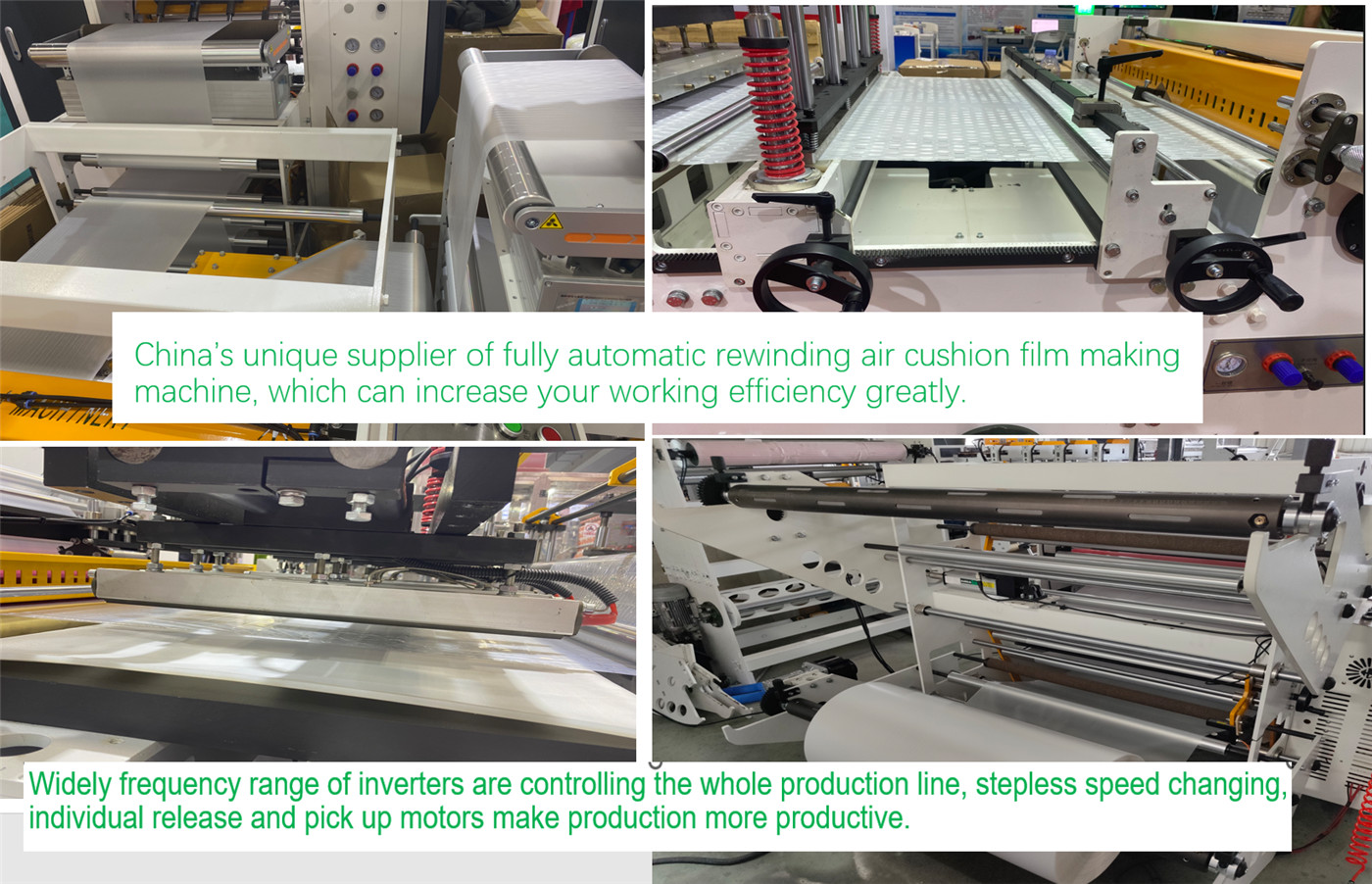

1. The whole machine adopts frequency conversion to control the whole production line, with stepless speed change and independent feeding and retrieving motor, which improves production efficiency.

2. The film production line adopts pneumatic shaft design in the winding and unwinding part, which is convenient for loading and unloading of products.

3. Built-in automatic homing, automatic alarm, automatic shutdown and other functions to optimize the operating efficiency of the machine.

4. The machine adopts a fully automatic EPC device in the unwinding part to ensure the uniformity of film production.

5. The winding and unwinding part is equipped with a high-function potential sensor to ensure continuous film feeding and stable unwinding.

6. This machine is equipped with a grating device integrated with motor reducer and brake, which eliminates the belt chain and noise, and improves the stability and precision of the machine.

7. The unwinding process of the machine adopts optical eye EPC technology, which makes the film smoother and tighter, and provides a cleaner and safer packaging solution.

8. Our air cushion packaging machine is one of the most upgraded models in China, and more and more leading packaging companies choose to upgrade their air column cushion bag production lines with our advanced machines.

Application& related items

Our Factory