Automatic Air Bubble Film Bag Machine

Machine Introduction

Fully automatic air cushion film bag making machine is an efficient and reliable solution for producing high-quality packaging products. Specifically designed to handle PE coextrusion packaging film, it is ideal for packaging electronics, shredded items and other products that require a center fill for finer packaging output.

As a leading manufacturer of fully automatic plastic bubble film bag making machines in China, the machines we provide are characterized by power saving, high efficiency and easy operation. Here are some of the features that make this machine stand out:

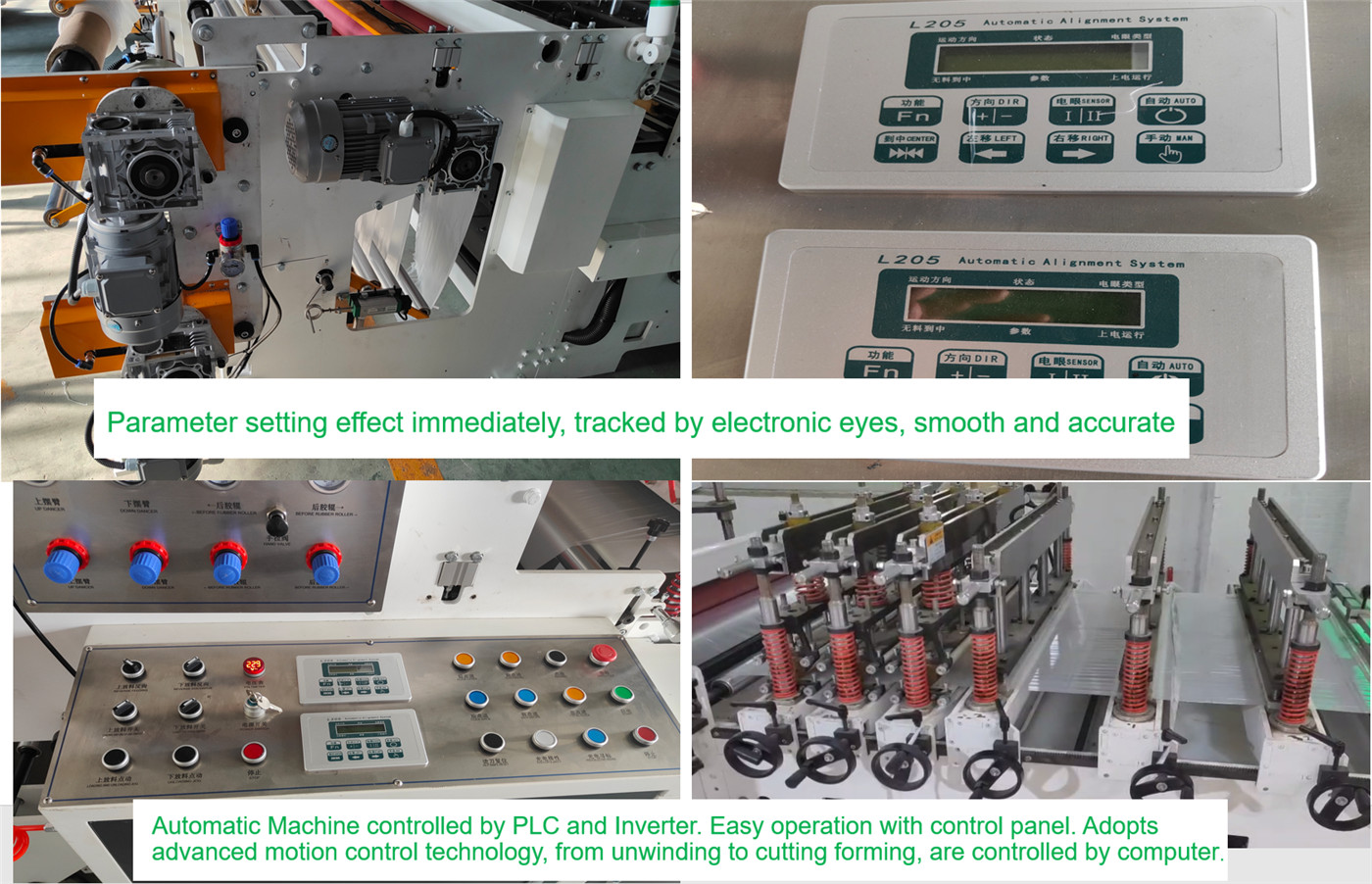

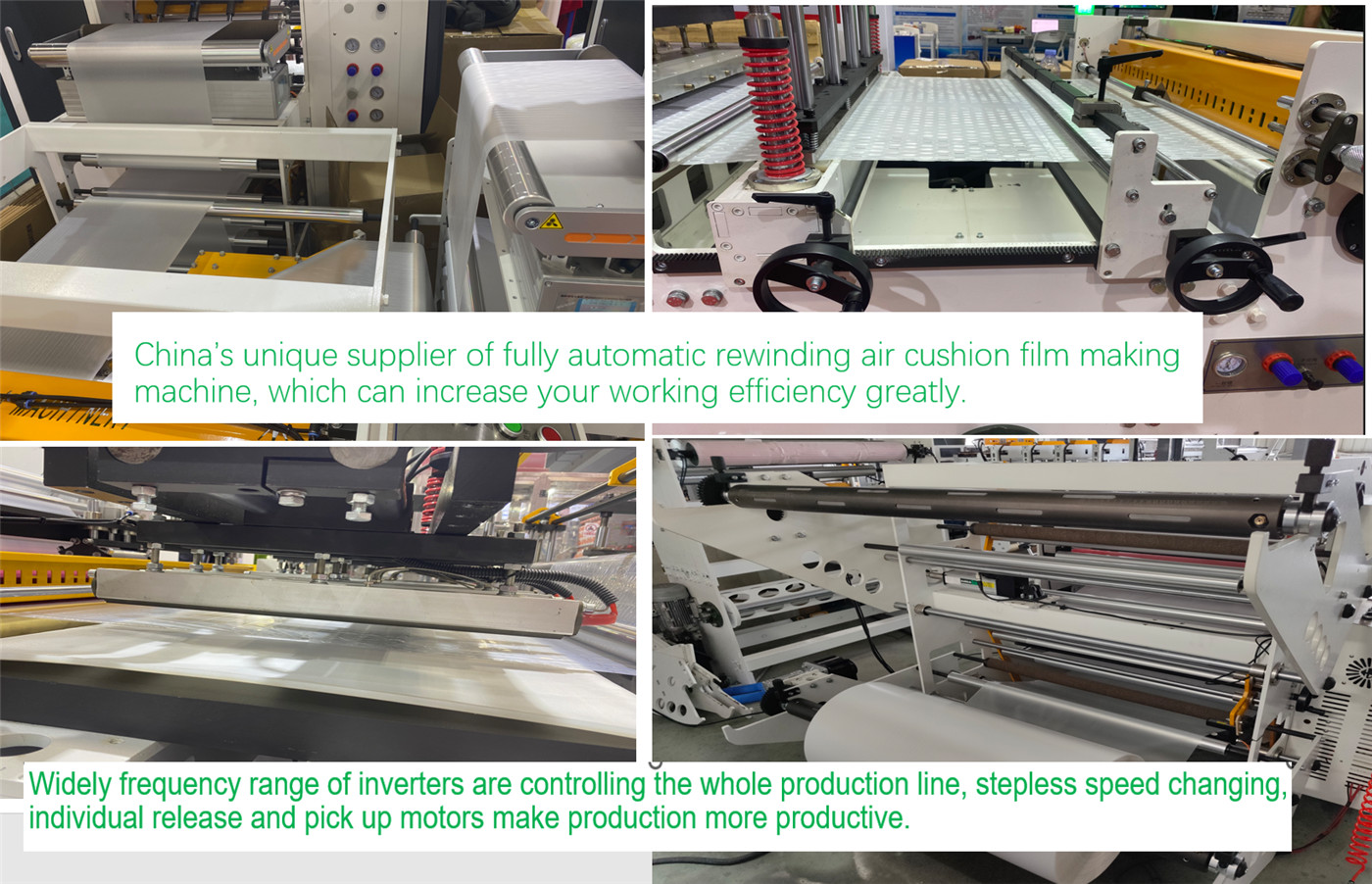

1. The production line adopts broadband frequency conversion speed regulation, stepless speed change, independent retractable motor, and improves production efficiency.

2. The air cushion film production line is equipped with an air shaft at the rewinding and unwinding place, which is convenient for loading and unloading products.

3. The machine has the functions of automatic homing, automatic alarm, automatic shutdown, etc., to ensure efficient and safe operation.

4. The fully automatic bubble packaging machine is equipped with a fully automatic EPC device in the unwinding part to ensure uniform film output.

5. The winding and unwinding part is equipped with a high-function potential sensor to ensure continuous film feeding and stable unwinding.

6. The air bubble film bag making machine adopts the grating device integrated with the motor reducer and the brake, which does not need a belt chain and has low noise. Its stability and precision are much higher.

7. The fully automatic PE bubble film bag making machine is equipped with photoelectric eye EPC for unwinding, and the film produced is flatter and tighter.

8. Although not the oldest machine, our upgraded model is one of the most advanced models in China. It has won high praise from well-known packaging companies, and they are upgrading their air column cushioning bag production lines with our machines.

Application& related items

Our Factory