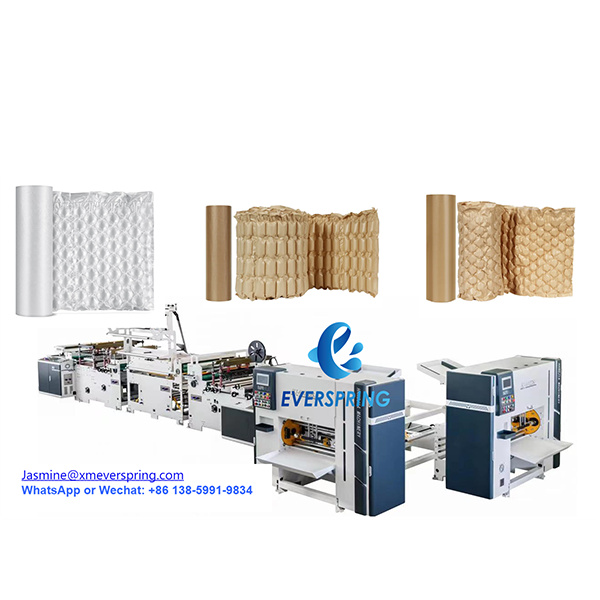

Paper Air bubble film making machine

Machin Introduction

Our paper bubble bag packaging film making machine is also known as automatic paper bubble film bag making machine, paper bubble bag air cushion film making machine, or paper bubble machinery. It is designed for DHL and FedEx, but can be used for other applications as well. This machine seals the air channel, seals the film edge, and cuts a line across the line, which is suitable for PE co-extrusion packaging film. It is widely used in the packaging of electronic products, scraps, luggage and other items, providing exquisite and beautiful packaging.

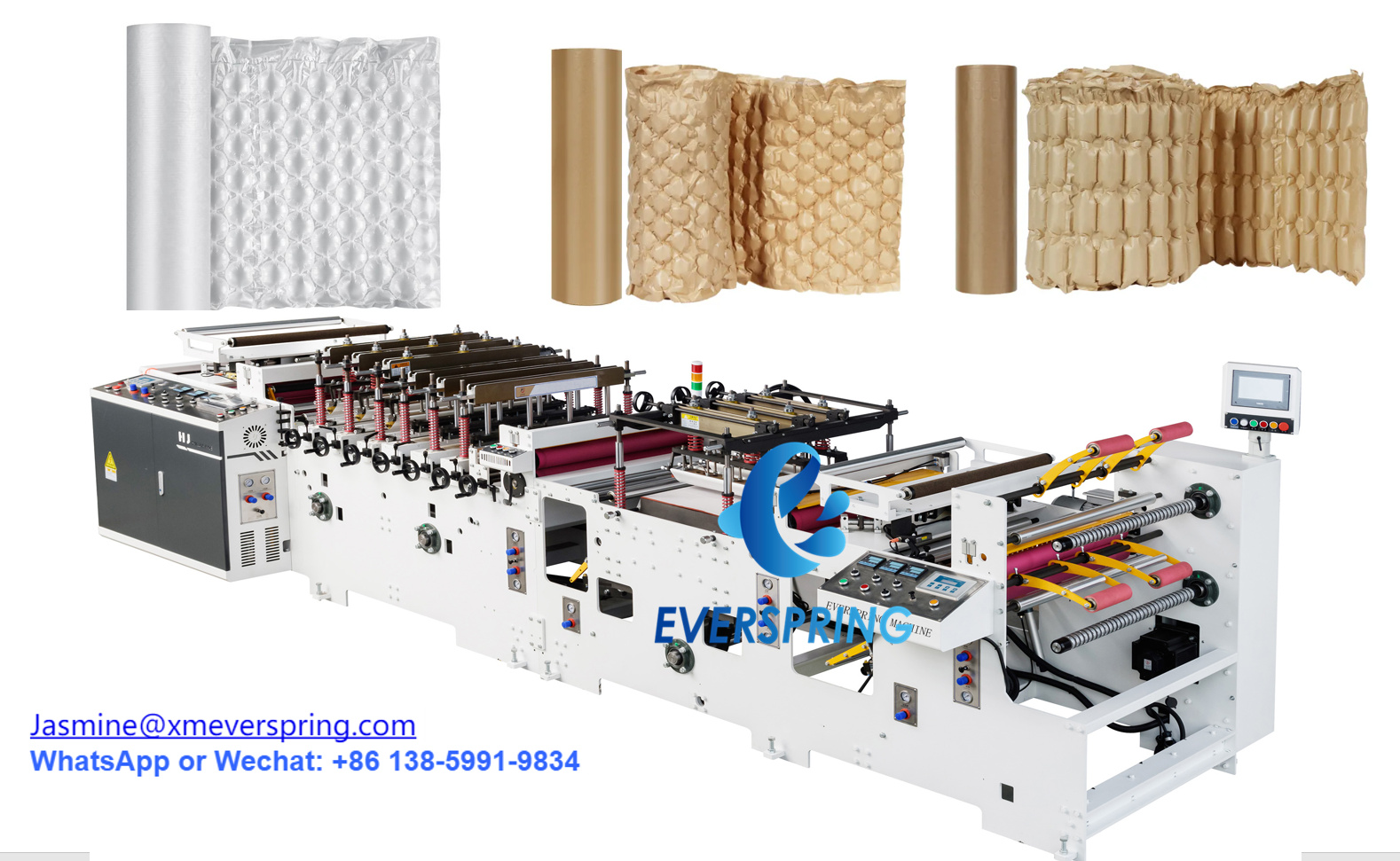

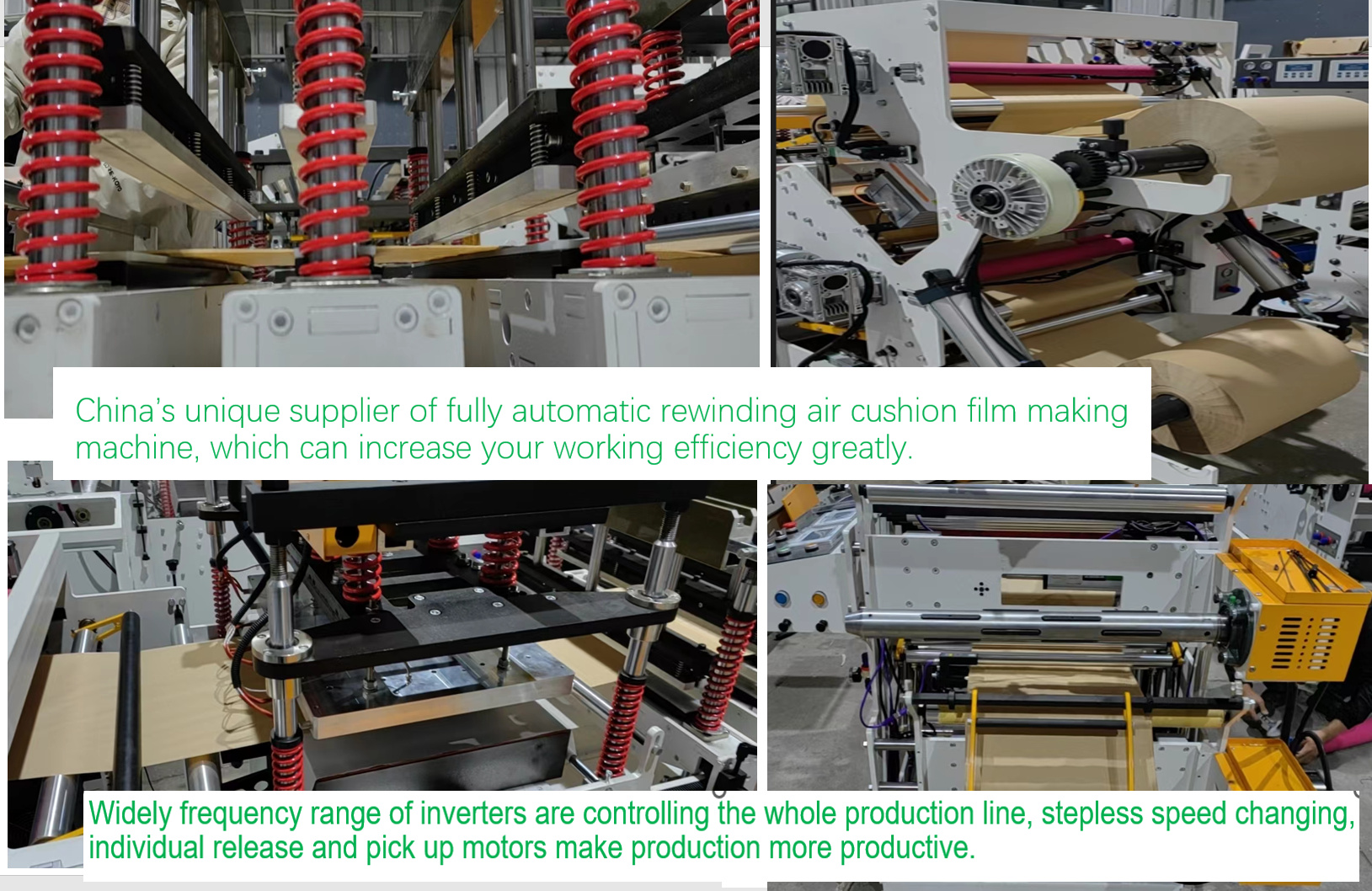

Our single ply paper air bubble film making machine is power saving, efficient and easy to operate. It is a mechatronic device capable of producing high-quality bubble wrap at a speed suitable for a large-scale production environment. Frequency conversion speed regulation has a wide range, controls the entire production line, and realizes stepless speed change. Independent release and pick-up motors make production more efficient.

Loaded and unloaded products are easily handled with this machine thanks to the air shafts in the winding and unwinding section. It is equipped with various functions such as automatic homing, automatic alarm and automatic stop to ensure precision and reliability. There is also a fully automatic EPC device in the unwinding part to make the film uniform.

The winding and unwinding part adopts high-function potential sensor to ensure continuous film feeding and stable unwinding. This machine adopts the grating device integrated with motor reducer and brake, no belt chain, no noise, more stable and more accurate operation. The unwinding of this machine adopts optical eye EPC, which makes the film smoother and tighter, further enhances its appearance, and creates better products for your packaging needs.

Although not the longest machine in the market, our model is the most upgraded in China, and more and more well-known packaging companies turn to our machine to upgrade their air column cushioning bag production lines.

Application& related items

Our Factory