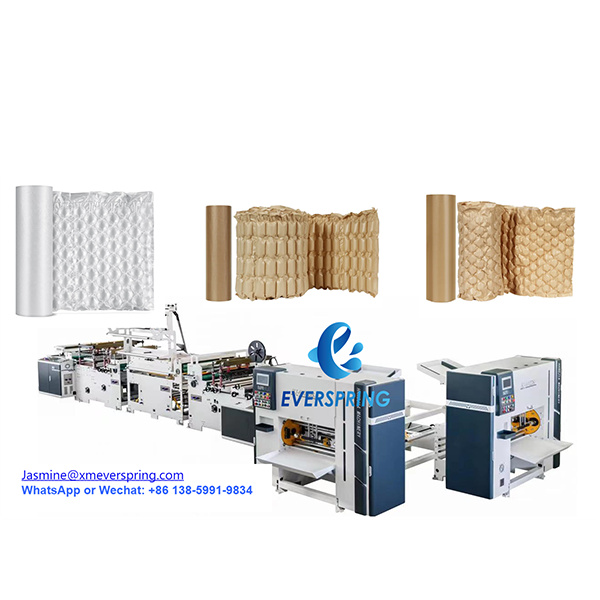

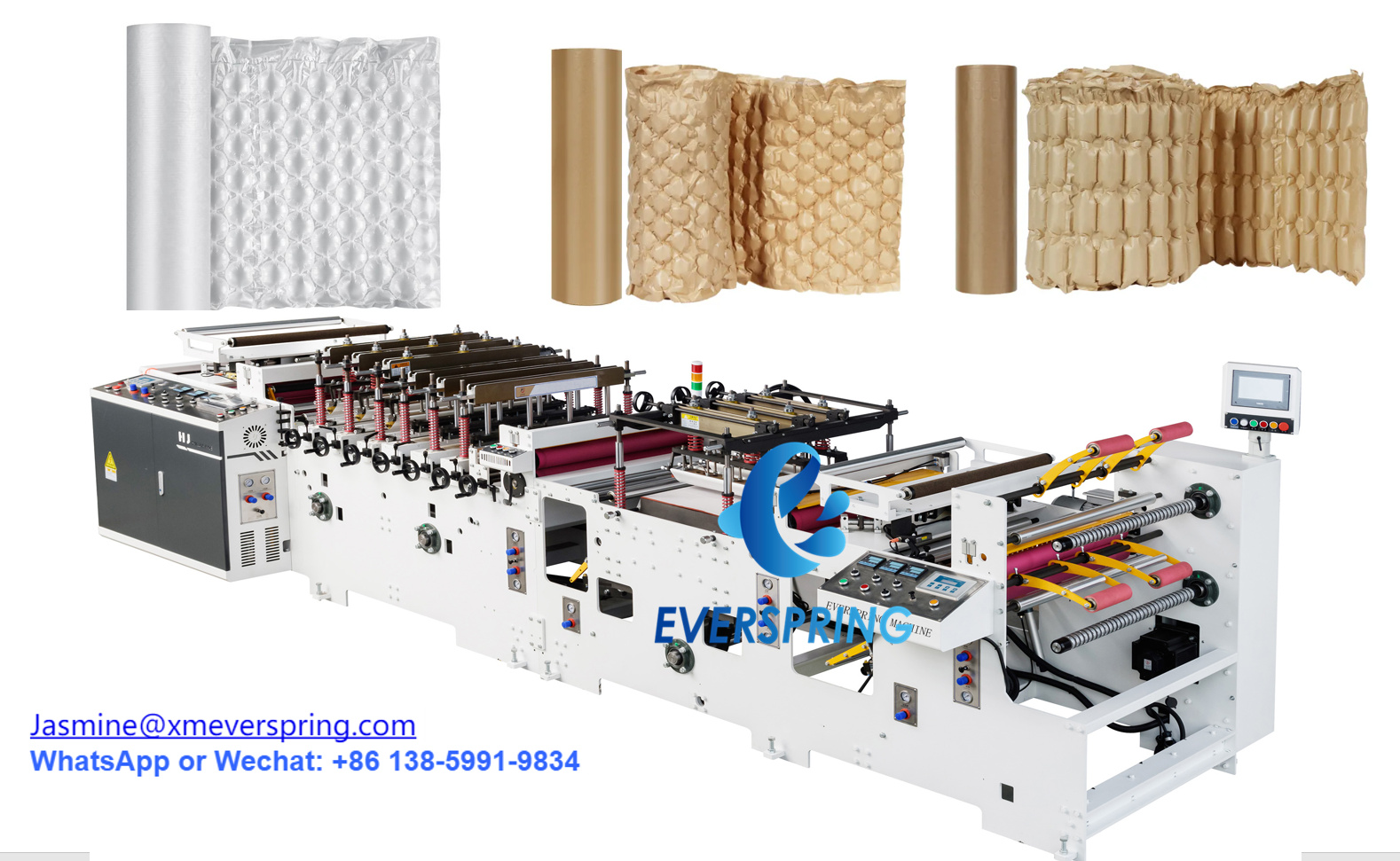

Paper Air bubble cushion film bag making machine

Machin Introduction

Rewrite: Paper air pillow film making machine, paper air pillow film making machine, paper air pillow buffer film production line, paper air pillow coil production line to produce PE co-extruded packaging film, with sealing air channel, sealing film edge, horizontal - cut into a line . This equipment is suitable for packaging electronic products, broken products, bags and other products that require exquisite and beautiful packaging. This mechatronic device is energy efficient, efficient and easy to operate.

advantage:

1. Paper air bag machine, paper air bag film rolling machine, paper air pillow packaging machine have simple linear structure, easy to install and operate.

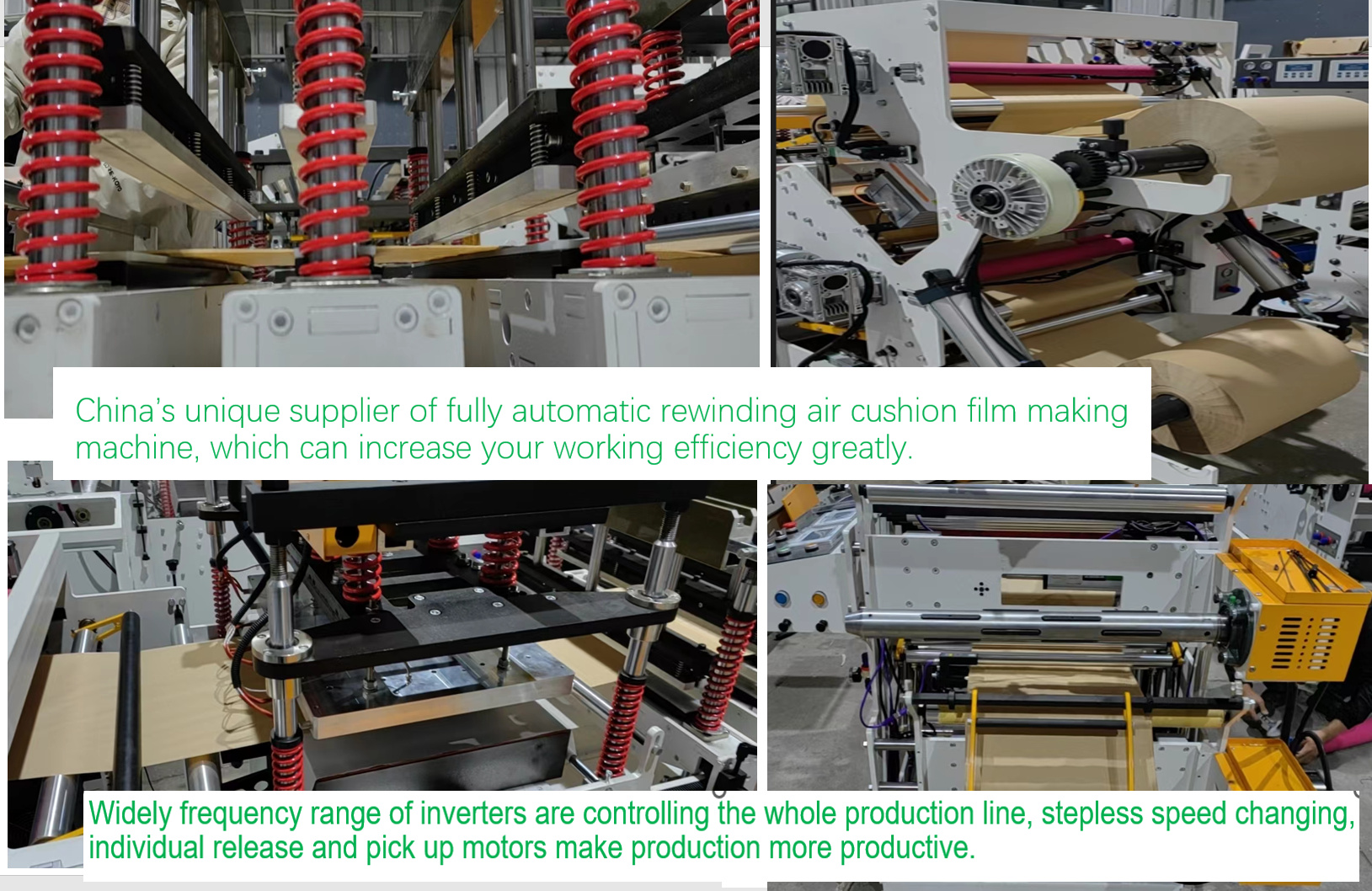

2. This machine adopts high-quality components, such as pneumatic components, electrical systems, and operating components. All other machine parts are from the best suppliers in the machine supply chain in China, which enhances the stability of the machine compared with others. Our customers require little after-sales support.

3. Machine operation is automated and highly intelligent. We are proud to be the only automatic rewinder supplier in China.

4. Paper air cushion film roll production line, paper air cushion film making machine, paper air cushion film production line, and paper air cushion film coil processing production line adopt advanced motion control technology and are controlled by computer. The whole process of paper air cushion film from unwinding to cutting and forming is controlled by computer system.

5. The automatic machine is controlled by a programmable logic controller (PLC) and a frequency converter, and it is very easy to operate with a control panel.

6. The parameter setting takes effect immediately, and electronic eye tracking ensures smooth and accurate process.

7. The whole production line is controlled by frequency converter, which has a wide range of frequency conversion speed regulation and stepless speed change. This, combined with separate release and pick-up motors, enables more efficient production of paper air cushion films.

Application& related items

Our Factory