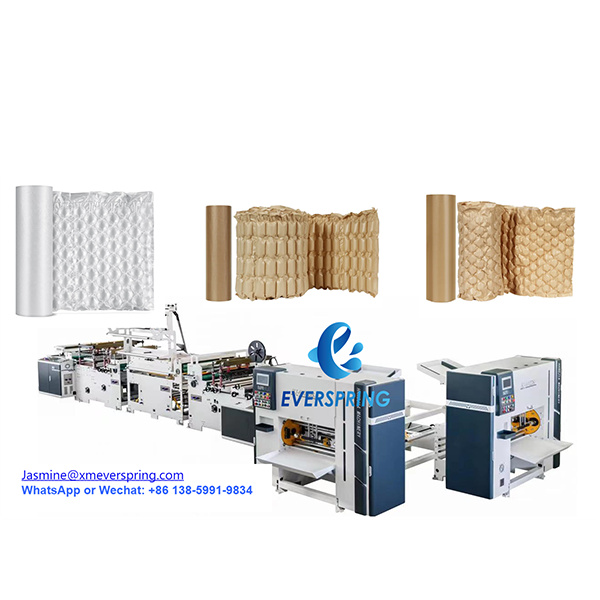

Paper Air bubble cushion film Making Machine

Machin Introduction

Biodegradable paper Bubble Film Wrap Recycling Green Air Bubble Film Machine,

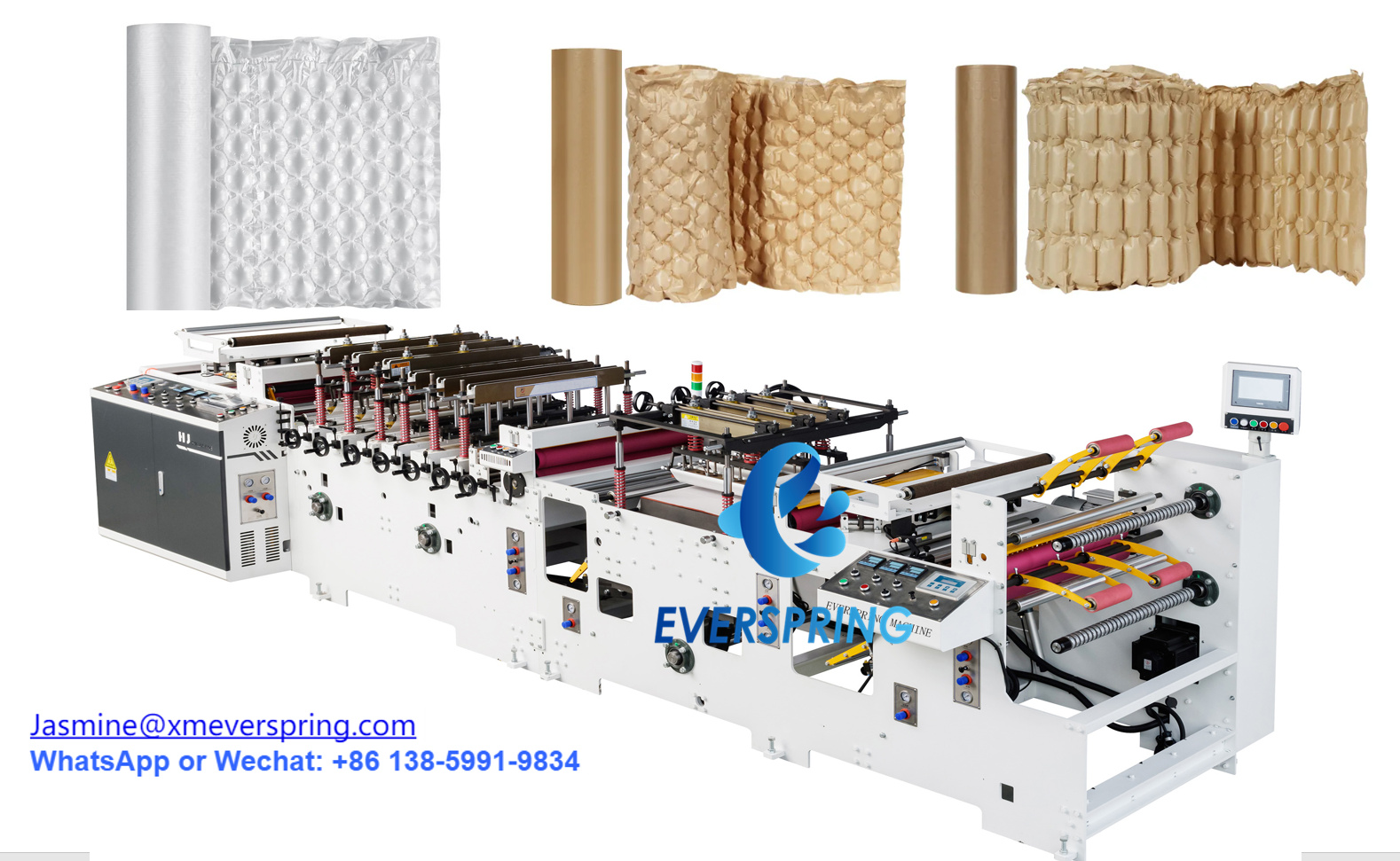

Paper inflatable bubble bag bag making machine is designed to seal the air path, seal the film side and cross-cut a high-efficiency production line. The machine is ideal for use with PE coextrusion packaging films, making it a versatile addition to any production facility. The resulting product is refined and aesthetically pleasing and suitable for packaging electronics, shredded products, bags and other items that require a center fill.

Our fully automatic air bubble film paper bag making machine is the perfect solution for companies requiring high speed and efficient air bubble film production. These machines produce high quality air bubble film in a mass production environment for high production rates.

Features of our machines include:

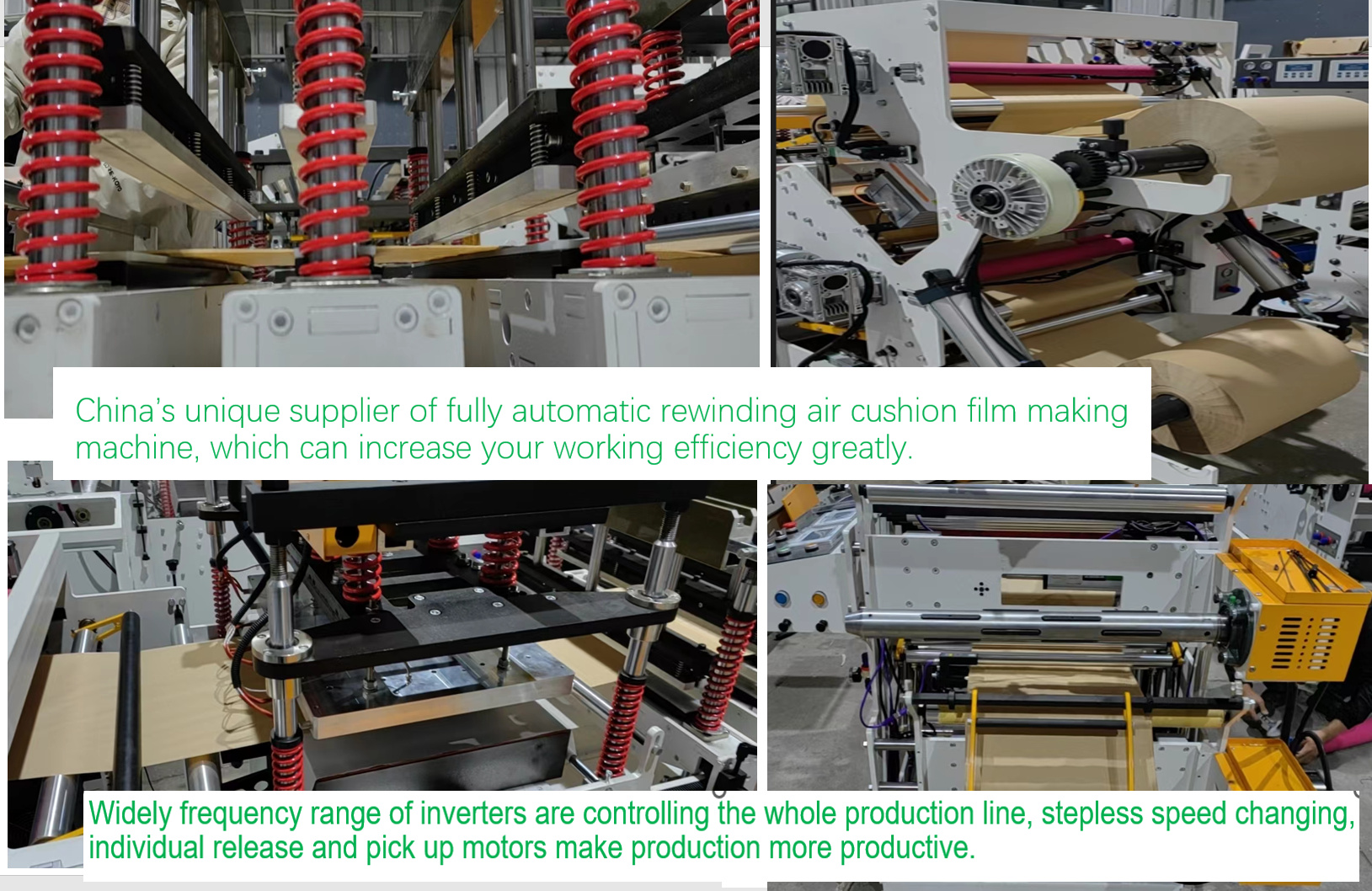

1. The entire production line is controlled by a frequency converter with a wide frequency range, which can realize stepless speed change. Separate release and pick-up motors further increase productivity.

2. The high-speed inflatable packaging film bubble cushion air bag packaging machine adopts an air shaft in the unwinding and unwinding part, which makes product loading and unloading easier.

3. The machine has automatic homing, automatic alarm and automatic stop functions to achieve the best efficiency.

4. The paper air bubble film side sealing bag making machine is equipped with an automatic EPC device in the unwinding part to ensure the uniformity of the film.

5. High-function potential sensor is used to ensure continuous film discharge and stable unwinding.

6. The paper bubble film bag making machine adopts a grating device that combines the motor reducer and the brake into one, which reduces noise and improves stability and precision.

7. The unwinding function of the factory direct-selling automatic air bubble cushion protective film making machine adopts photoelectric eye EPC to make the film smoother and tighter.

8. Although not the machine with the longest history, our machine is the most upgraded model in China. More and more famous packaging companies are upgrading their air column cushion bag production lines with our machines.

Application& related items

Our Factory