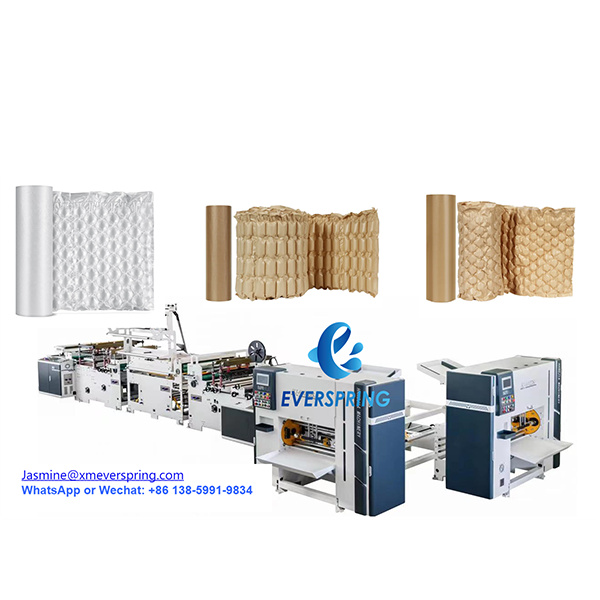

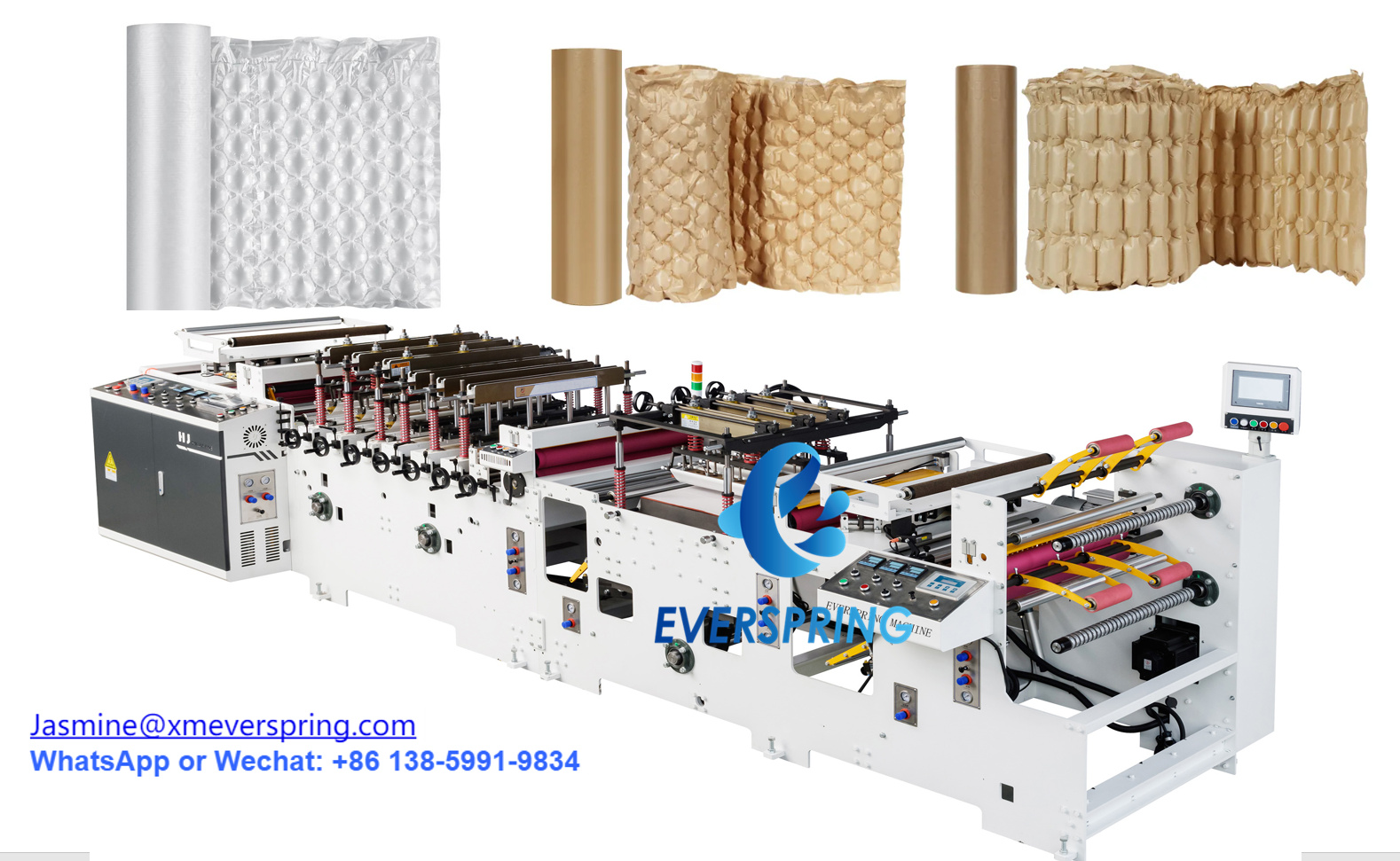

Automatic Paper Air Bubble Film Bag Machine

Machin Introduction

We have manufactured an advanced automatic paper air cushion film making machine, also known as automatic paper air cushion film rolling machine, which integrates airway sealing, film edge sealing and cross cutting. This machine is specially designed for PE co-extrusion packaging film, and is widely used in the packaging of electronic products, leftover materials, luggage and other items that require exquisite packaging.

Our unique automatic paper air pillow bag making machine is the only one of its kind in China. It provides a cost-effective solution for enterprises to efficiently and quickly produce high-quality air bubble films suitable for large-scale production environments.

Some key features of our Automatic Paper Bubble Cushion Film Making Machine are:

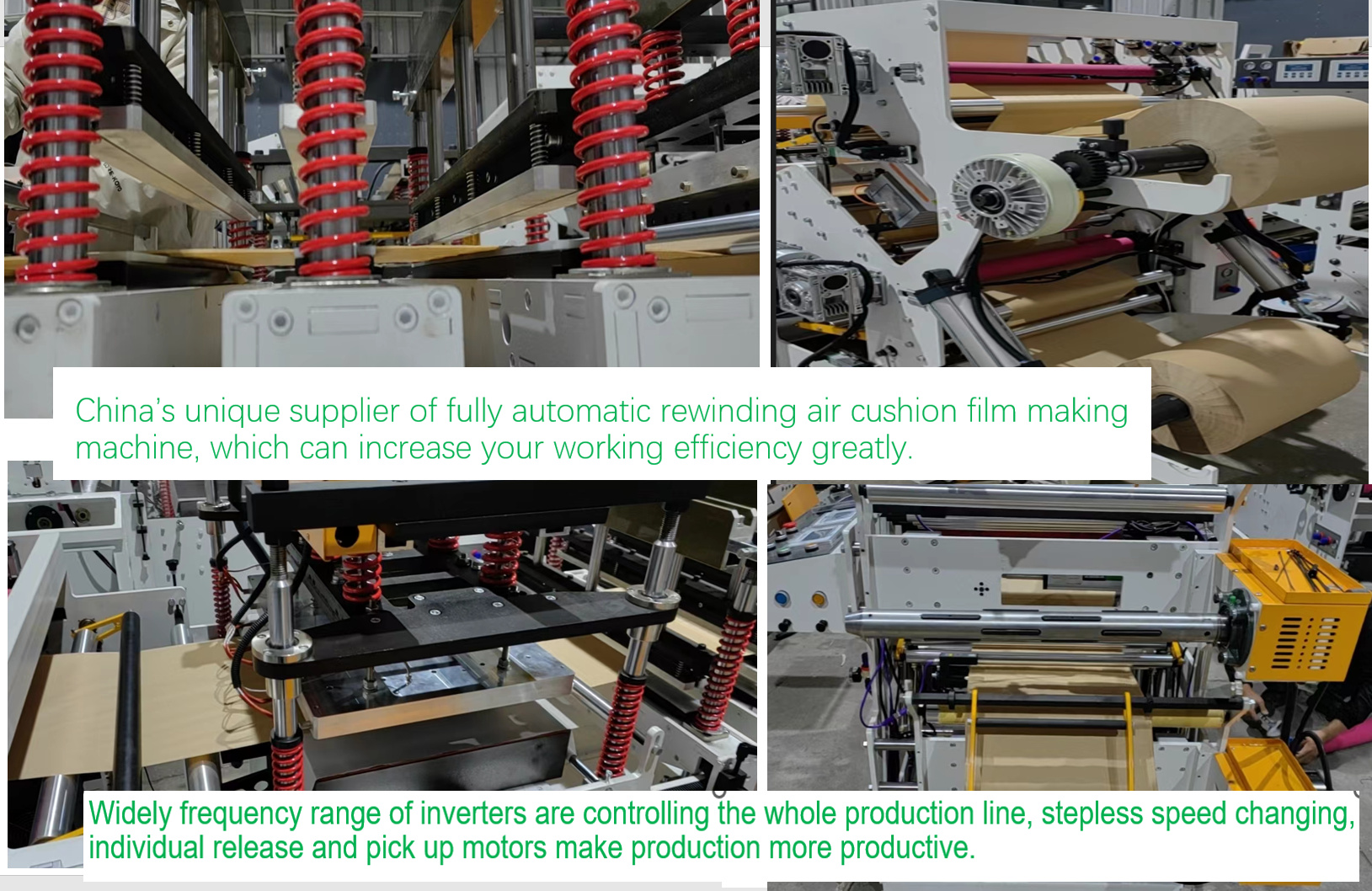

1. The production line is controlled by a wide range frequency converter with stepless speed change. Independent retractable motor makes production more efficient.

2. The automatic paper air cushion film production line adopts air shaft design in the unwinding and unwinding part, which is convenient for loading and unloading products.

3. The machine has automatic homing function, automatic alarm and shutdown function, which is very user-friendly and convenient.

4. The automatic paper blister packaging machine is equipped with a fully automatic EPC device in the unwinding part to ensure the uniformity of the film.

5. The rewinding and unwinding part of the machine is equipped with a high-performance potential sensor, which can ensure continuous film feeding and unwinding stability even at high speed.

6. In order to ensure higher stability and precision, our air bubble film paper bag machine adopts motor reducer and brake integrated device, which runs without belt chain and noise.

7. The unwinding system of the automatic PE bubble film bag making machine is equipped with a photoelectric eye EPC, which makes the film smoother and tighter.

8. Our machines are the most upgraded models in China and are very popular. A well-known packaging company upgraded our air column air cushion bag production line.

Application& related items

Our Factory