Paper Air cushion bag roll making machine

Machin Introduction

Paper air Bubble Pouch Bag Packaging Film Making Machine Price, Automatic paper Air Bubble Film Bag Making Machine, Paper Air Bubble Bag Air Cushion Film Making Machine, Paper Air Bubble Machinery.

Paper Air Bubble Bag Converting Machine for DHL

FedEx also called HDPE or Paper Air Bubble Film Making Machine is sealing air way, seal film side and cross-cut in one line, suitable for PE co-extruded packaging film. The products are widely used in packaging electronic products, shredded products, bags and other items filled in the center to get the more refined and beautiful packaging products. Paper Air Bubble Bag Machine, Single-Layer Paper Air Bubble Film Making Machine is power saving, high efficiency and simple operation, mechatronics equipment.

The paper air filler cushion solution is 100% biodegradable and recyclable and Made from paper with a starch based sealer, and it is Alternative to plastic air pillow, which can Save storage, Inflate on demand

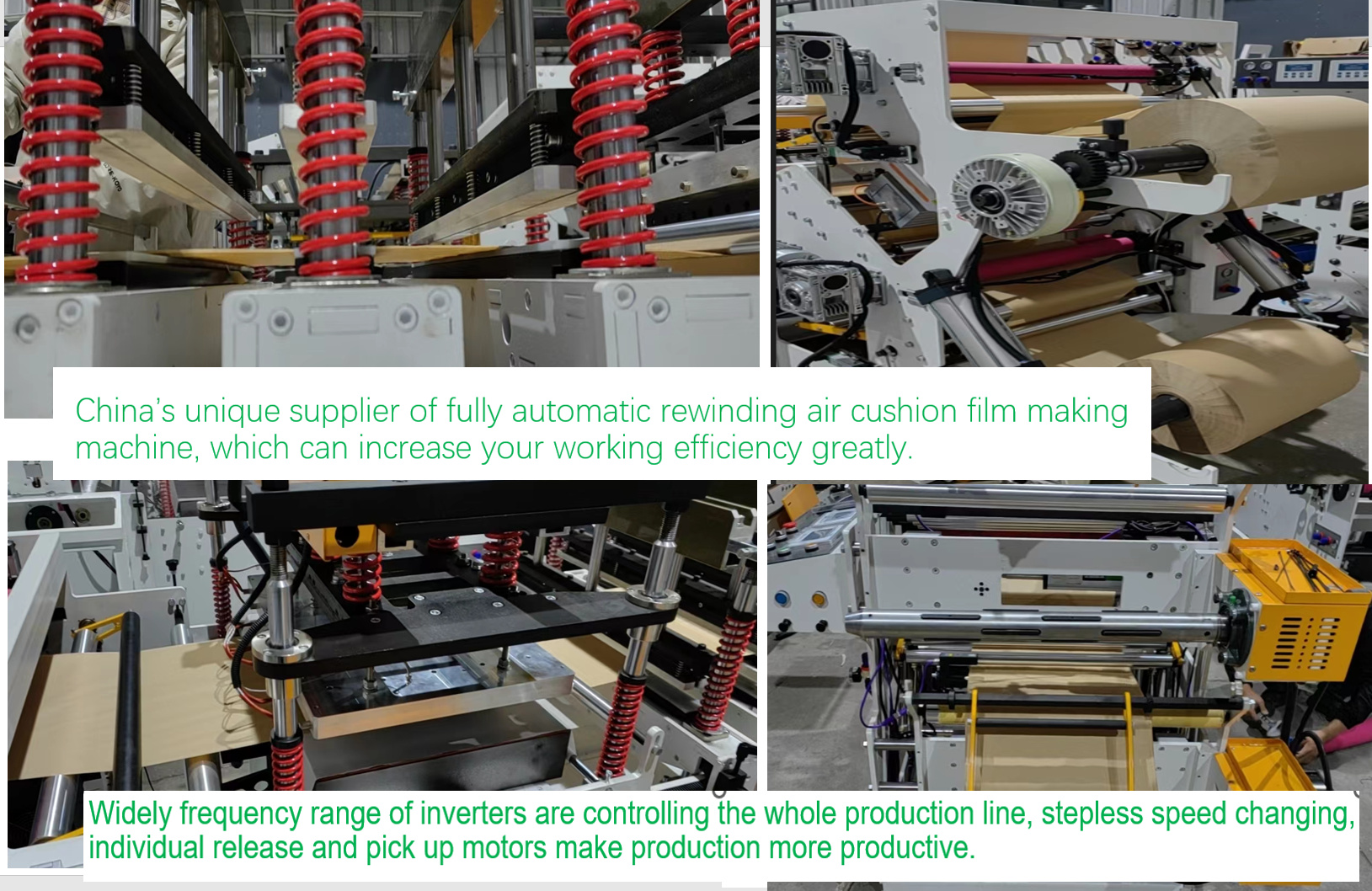

1, Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and pick up motors make production more productive.

2, High Speed Inflatable Packaging Film Bubble Cushion Air Bag Packing Machine is easy to load and unload products with air shafts in the rewinding and unwinding parts

3, The machines have functions like auto homing, auto alarming and auto stop etc.

4, Air Bubble Film Side Sealing Bag Making Machine is equipped with fully automatic EPC device on unwinding part to make film even.

5, Rewinding &unwinding parts are with high function potential sensor to ensure continuous film delivery and stable unwinding.

6, Air Bubble Film Bag Making Machine adopts inter-grating device of motor reducer brake all-in-one, without belt chains or noise. Its stability &precision are much higher.

7, machine’s unwinding is with photo-eye EPC to make film more flat and tighter.

8. Not the longest history machine but the most upgraded model in China. More and more famous packaging companies upgrade air column cushion bag production line with our machines.

Application& related items

Our Factory