Automatic paper air pillow film roll making machine

Machin Introduction

Automatic paper air filled bag making machine, Automatic paper void fill cushion bag making machine, automatic inflatable paper pillow wrap making machine.

Automatic paper air cushion film making machine also called Automatic paper air cushion film rolls making machine is sealing air way, seal film side and cross-cut in one line, suitable for PE co-extruded packaging film. The machine adopts microcomputer servo control, fast length adjustment, having the function of automatic counting, photoelectric tracking, false alarm. The host discharging of material is driven by variable frequency motor, changing speed smoothly, high speed downtime, safe and reliable, intelligent control constant temperature, even bottom sealing line, practical and solid, rewinding adopts frequency conversion, photoelectric automatic control, achieving the effect that unwinding coincides with rewinding.

Go Environmentally Friendly without adding additional cost to your packaging. With Automatic paper Air Bubble Film Bag Making Machine you can get a Bio-degradbale solution with added protection for your products. The Eco-Fills are made of flexible recycled paper to fill the voids and provide cushioning and ensuring you up to Zero Damages. They are made of unique FSC compliant papers that are compostable and fully degradable. The sealing layer on the inner is also made of bio plastics that degrade upon exposure and can be also be recycled as pulp and again put to use.

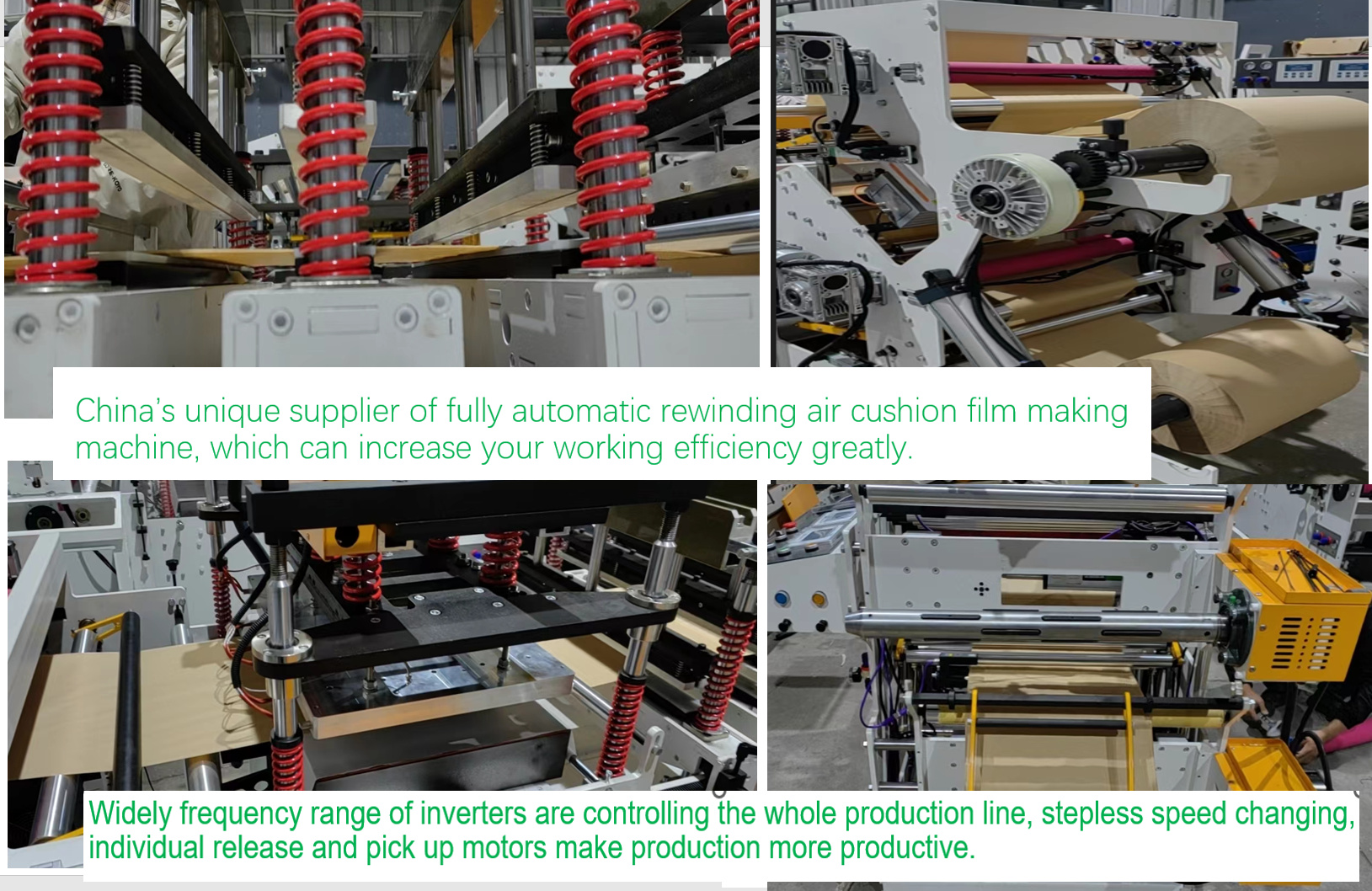

1, Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and pick up motors make production more productive.

2, Automatic paper air cushioning film production line is easy to load and unload products with air shafts in the rewinding and unwinding parts

3, The machines have functions like auto homing, auto alarming and auto stop etc.

4, Automated paper air pillow packaging making machine.is equipped with fully automatic EPC device on unwinding part to make film even.

5, Rewinding &unwinding parts are with high function potential sensor to ensure continuous film delivery and stable unwinding.

6, Air Bubble Film Bag Making Machine adopts inter-grating device of motor reducer brake all-in-one, without belt chains or noise. Its stability &precision are much higher.

7, machine’s unwinding is with photo-eye EPC to make film more flat and tighter.

8. Not the longest history machine but the most upgraded model in China. More and more famous packaging companies upgrade air column cushion bag production line with our machines.

Application& related items

After-Sales Service

1 year warranty.

Well experienced engineers to provide oversea service at your place.

7x24 hours online service to respond you anytime.

Installing, testing and training service.

Lifelong technical support.

Our Factory