Paper Air cushion film rolls making machine

Machin Introduction

Paper Airbag rolls making machine, Paper cushion bag rolls making machine, Paper filling bag rolls making machine, paper air Pillows rolls making machine, paper air Cushioning roll making machine

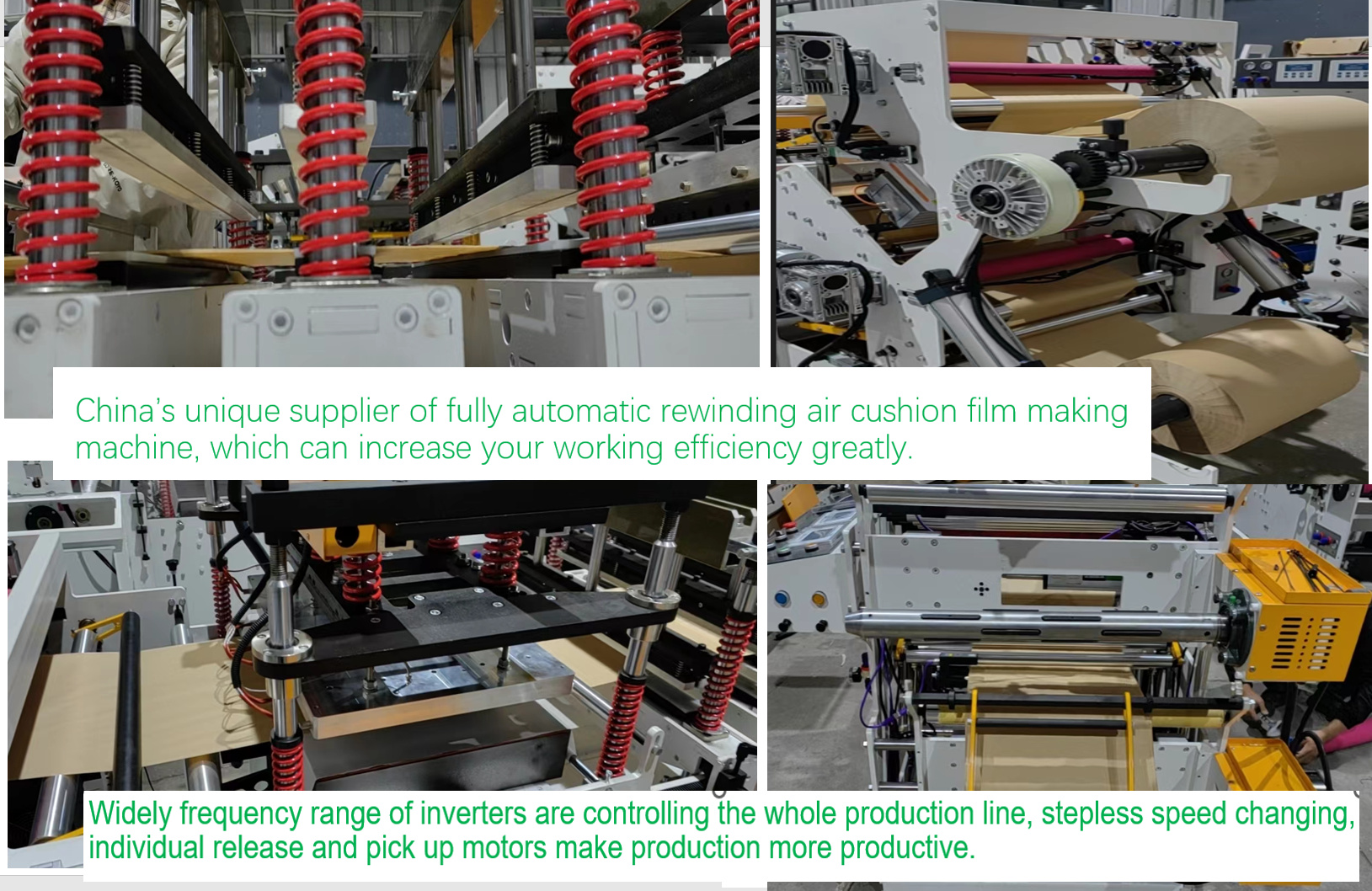

Paper air pillow air cushion reel machine, also known as paper air bag reel machine, is a production line integrating air channel edge sealing, film edge sealing and cross cutting. This machine is suitable for processing PE co-extrusion packaging film. The resulting product is ideal for packaging a variety of items such as electronics, scraps and bags, providing a more refined and aesthetically pleasing packaging solution. In addition, this double-row hoist pillow type air cushion roll machine and bio-air film air cushion roll production line is a mechatronic equipment with high efficiency, easy operation, and reduced power consumption.

Our paper air bag, pillow packaging, and air cushion bag making machine series are the best solutions for enterprises pursuing fast and high-grade air bubble film production. Use of these machines ensures a consistent output of high quality air bubble film, ideal for large scale manufacturing environments. These machines boast exceptional production speed and operating efficiency, making them reliable assets for businesses requiring fast and efficient output.

Our environmentally friendly paper packaging machinery inventory includes honeycomb mailer bag making machines and honeycomb paper bag making machines, which are the ideal solution for businesses looking for cost-effective quality bags. These machines are easy to use, require minimal maintenance and are versatile, making them ideal for large-scale production environments.

When it comes to reliable and efficient packaging machinery, look no further than our company. We offer a wide selection of machinery to suit your needs, including the latest in Paper Bubble Pack Roll Making, Paper Bubble Cushion On-Demand Making Machines and Paper Air Cushion Bubble Pack Bag Roll Making Machine products. We are committed to providing high-quality machinery designed to meet your business needs, while also providing excellent value for money. Contact us today to discuss your requirements and learn more about our comprehensive range of packaging machinery.

Application& related items

Our Factory