Air column cushion rolls making Machine

Machine Introduction

Air column cushioning roll making machine, Air column cushioning wrap roll production line, Air column cushioning wrap roll conversion line, Air column wrap roll production line, Air column cushioning wrap roll manufacture line, Air column cushioning wrap roll processing line.

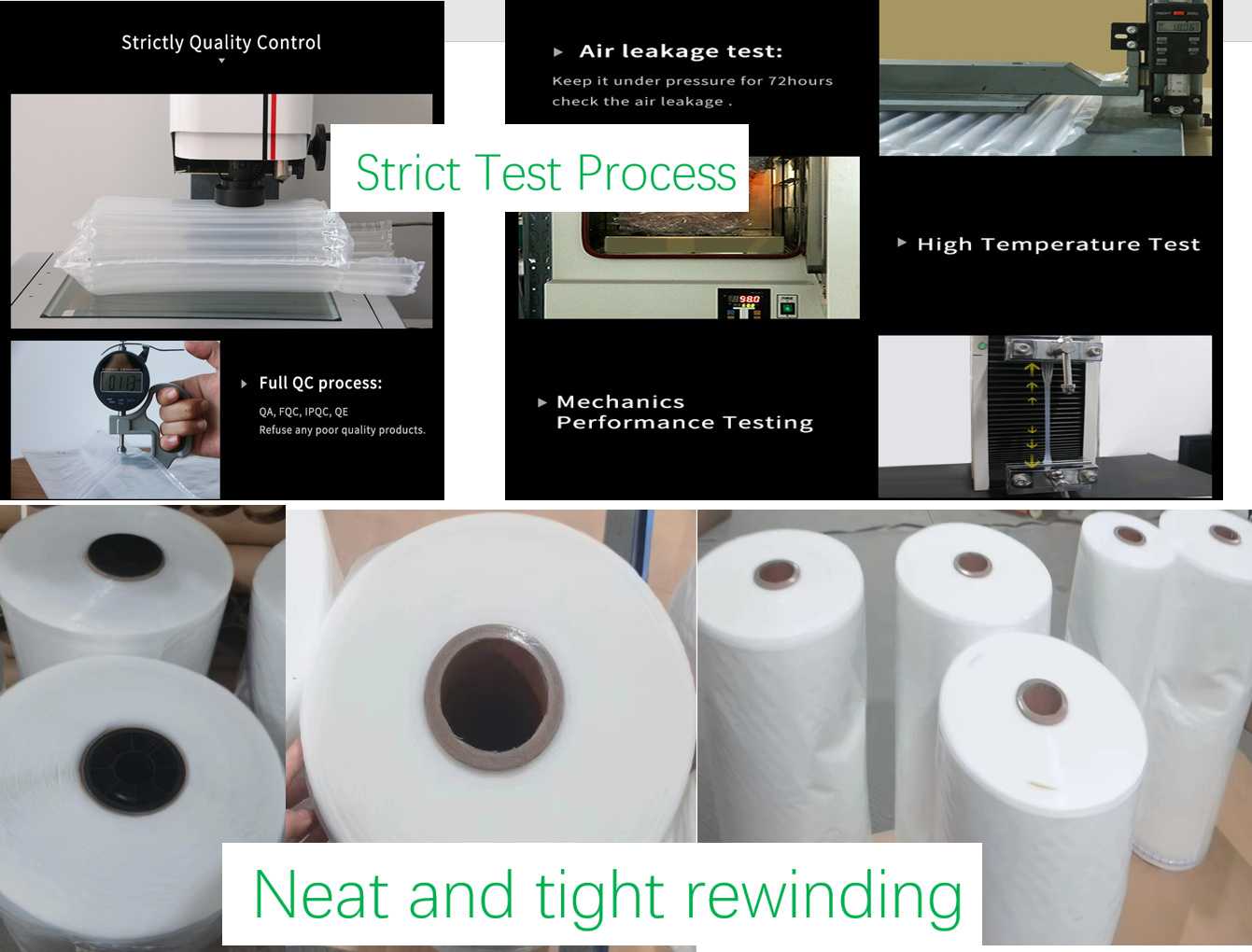

Air column cushion bag rolls making machine is a mechanical designed production line with all the advanced technology to make all kinds of airbag, cushioning bag, filling bag, paper airbag by PE Co-extruded film. Air pillows / air column packing rolls will be converted by our air column bag rolls making machine

Air column bag (inflatable air bags) is designed to meet the packaging needs of the business that need void fill and protect your products quickly and conveniently. Its flexible capabilities bridge the gap between traditional void fill and cushioning applications. You can create a column bag to fill any gaps and add a shock-absorbing layer of bubble wrap to every box. Air column packing provide superior protection compared to traditional shipping materials and also can be stored conveniently taking up a fraction of the space as peanuts and foam.

Advantages

Air column cushioning wrap rolls making machine, Air column cushioning wrap rolls production line, Air column cushioning wrap rolls conversion line, Air column wrap rolls production line, Air column cushioning wrap rolls manufacture line, Air column cushioning wrap processing line.

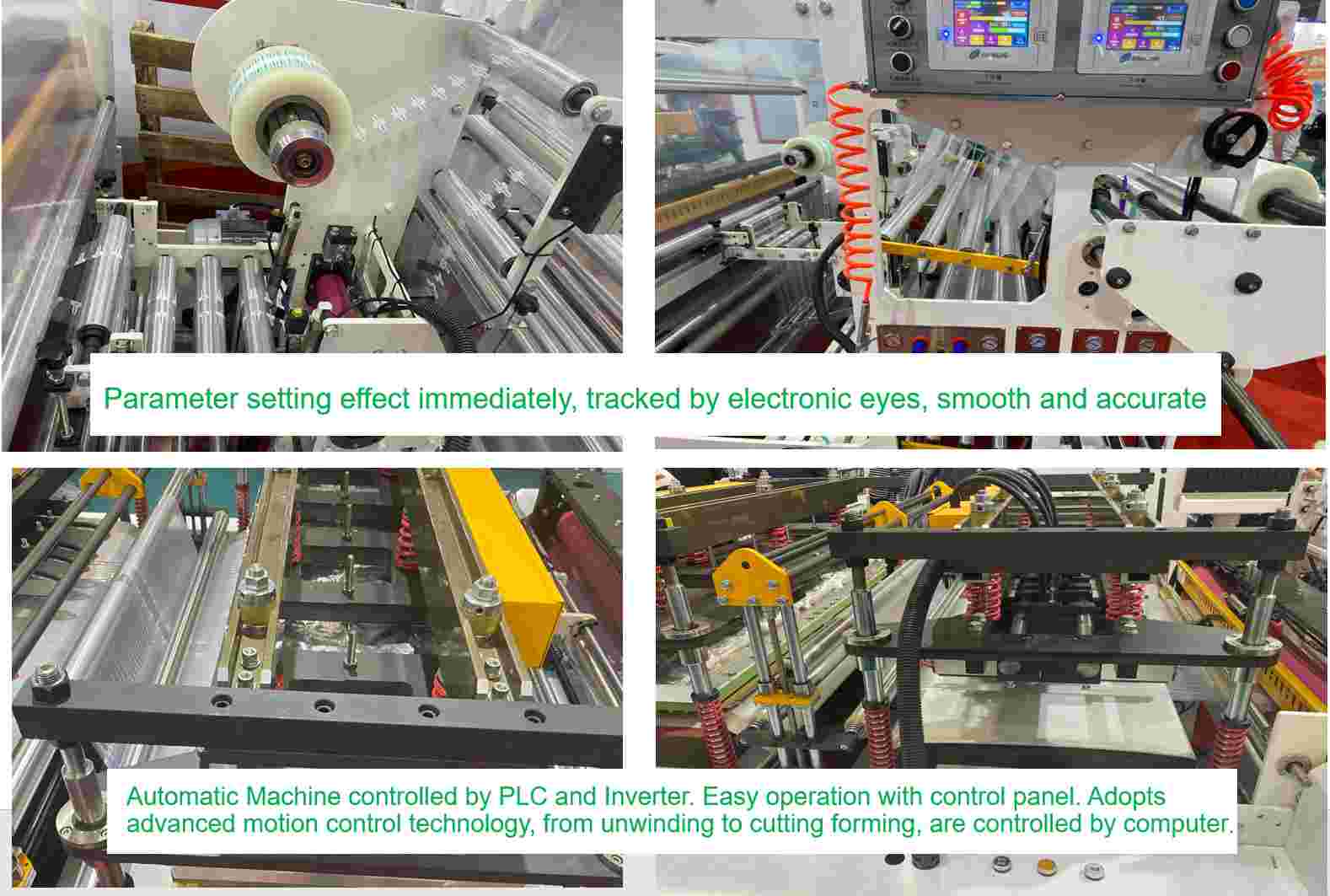

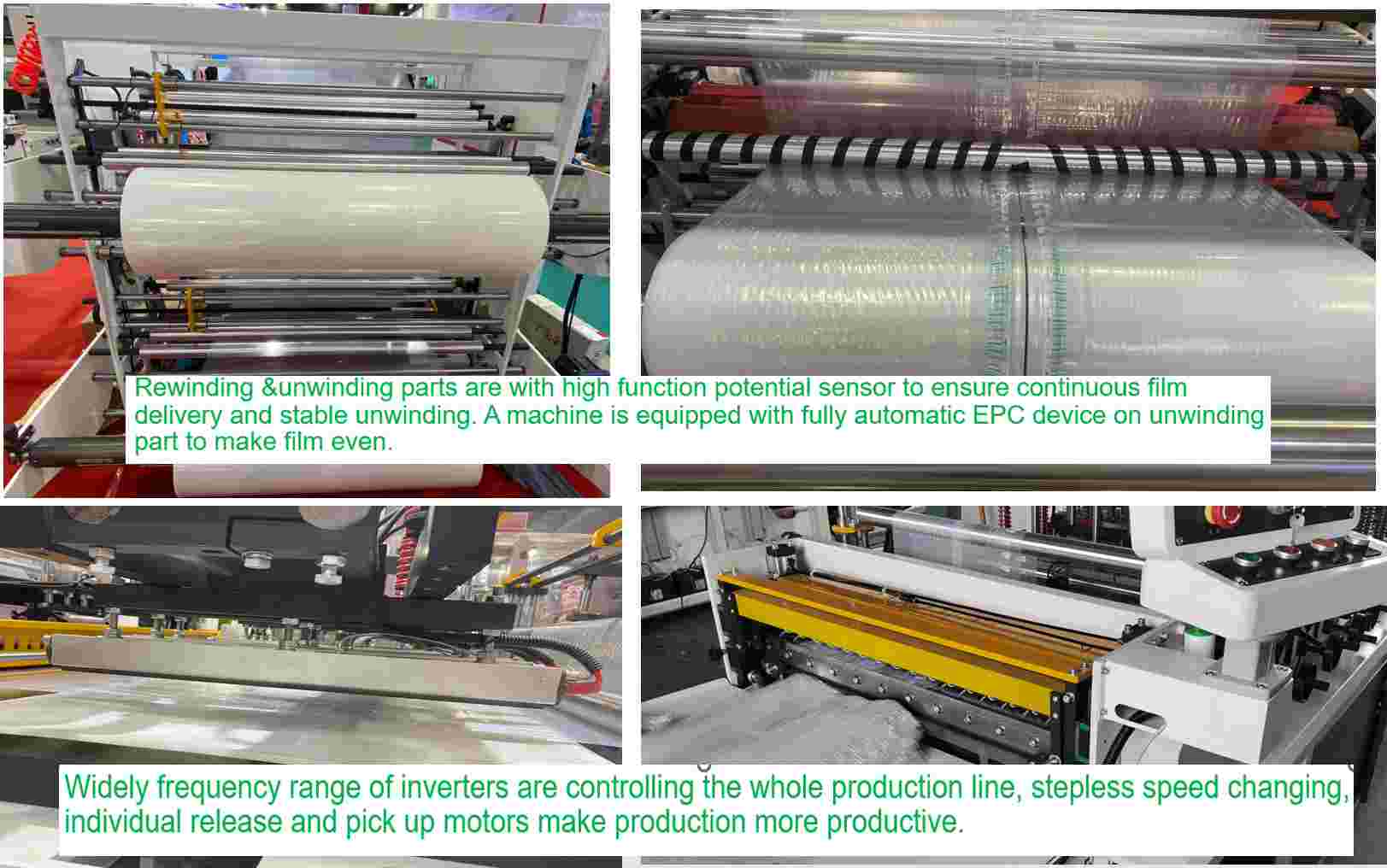

1. Our production lines are equipped with variable frequency speed regulation with a wide range, allowing stepless speed change and separate pay-off and pick-up motors to increase productivity.

2. The unwinding and unwinding part adopts the air shaft design, which is convenient for the loading and unloading of the product.

3. Machines A and B have the functions of automatic homing, automatic alarm and automatic shutdown, which is convenient and safe.

4. Machine A is equipped with a fully automatic EPC device in the unwinding part, and the production is uniform.

5. The high-performance potential sensor is used for unwinding and unwinding to ensure continuous film unwinding and stable unwinding.

6. The host machine of our company adopts an integrated device of motor, reducer and brake, which does not require a belt chain and reduces noise. This design improves stability and precision.

7. The unwinding function of machine B adopts optical eye EPC, and the film is tighter and smoother.

8. Customer can choose to combine A and B machines to increase productivity.

9. Our air column air cushion bag production line is the most upgraded model in China, and is adopted by more and more well-known packaging companies.

Application

Our Factory

Your Reliable Air Cushioning bag making machine Supplier in China