Air filled column bag rolls making machine

Machine Introduction

Air column pouch making machine, Air cushion bag making machine, Inflatable bag making machine, Air pillow bag making machine, Air packaging bag making machine, Air Tube Bag Filling rolls making Machine, Air Buffer Column Bag forming Machine.

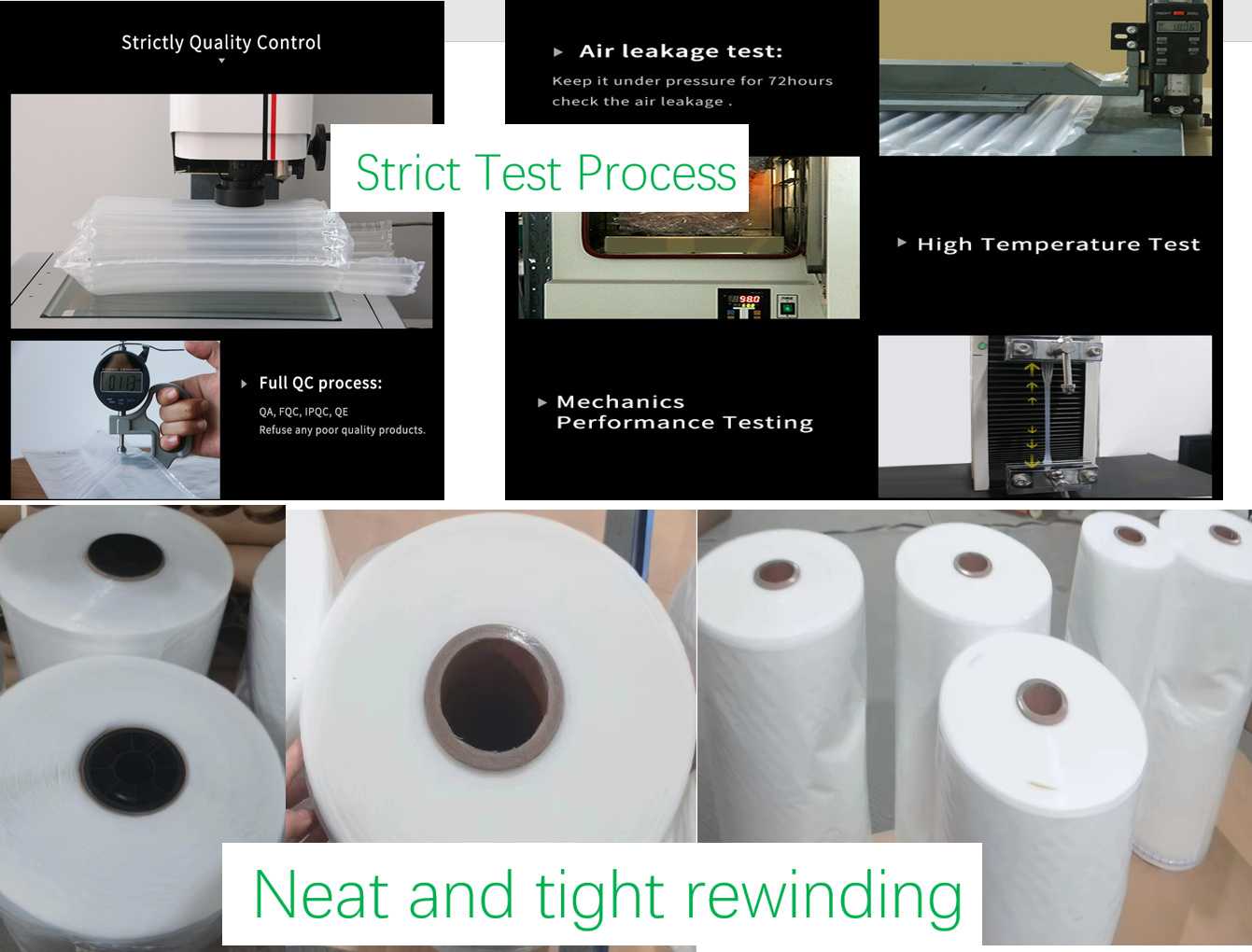

We are a professional air column bags rolls making machine manufacturer and supplier in China with 10 years of experience in design and production. We can customize your air column bag according to your product requirement. Customized air column bags can 100% protect your products from damage during transportation.

The main material of the air column bag is LDPE+15%PA (PA=Nylon). The air column cushion bag is moisture-proof, moisture-proof and waterproof. You don’t need to worry about the product getting wet.

Compared with traditional packaging and transportation materials, air filled bags for packaging can provide 360-degree three-dimensional comprehensive protection for your products, and minimize the damage rate of products during transportation.

The inflatable air column bag has a good shockproof effect, and the air tube bag can bear a weight of about 60-120KG after being inflated.

The inflatable air packaging bag is designed with multiple air columns, which can be automatically locked after inflation. Even if a single air column breaks, the other air columns still provide protection and can better avoid product breakage.

The air shock packaging can be inflated on demand. Before inflation, inflatable air packaging bag exists in the form of a roll, it can be stored conveniently taking up a fraction of the space as peanuts and foam, saves your warehouse space, and reduces your storage cost and transportation cost of packaging materials.

Advantages

Air column cushioning wrap rolls making machine, Air column cushioning wrap rolls production line, Air column cushioning wrap rolls conversion line, Air column wrap rolls production line, Air column cushioning wrap rolls manufacture line, Air column cushioning wrap processing line.

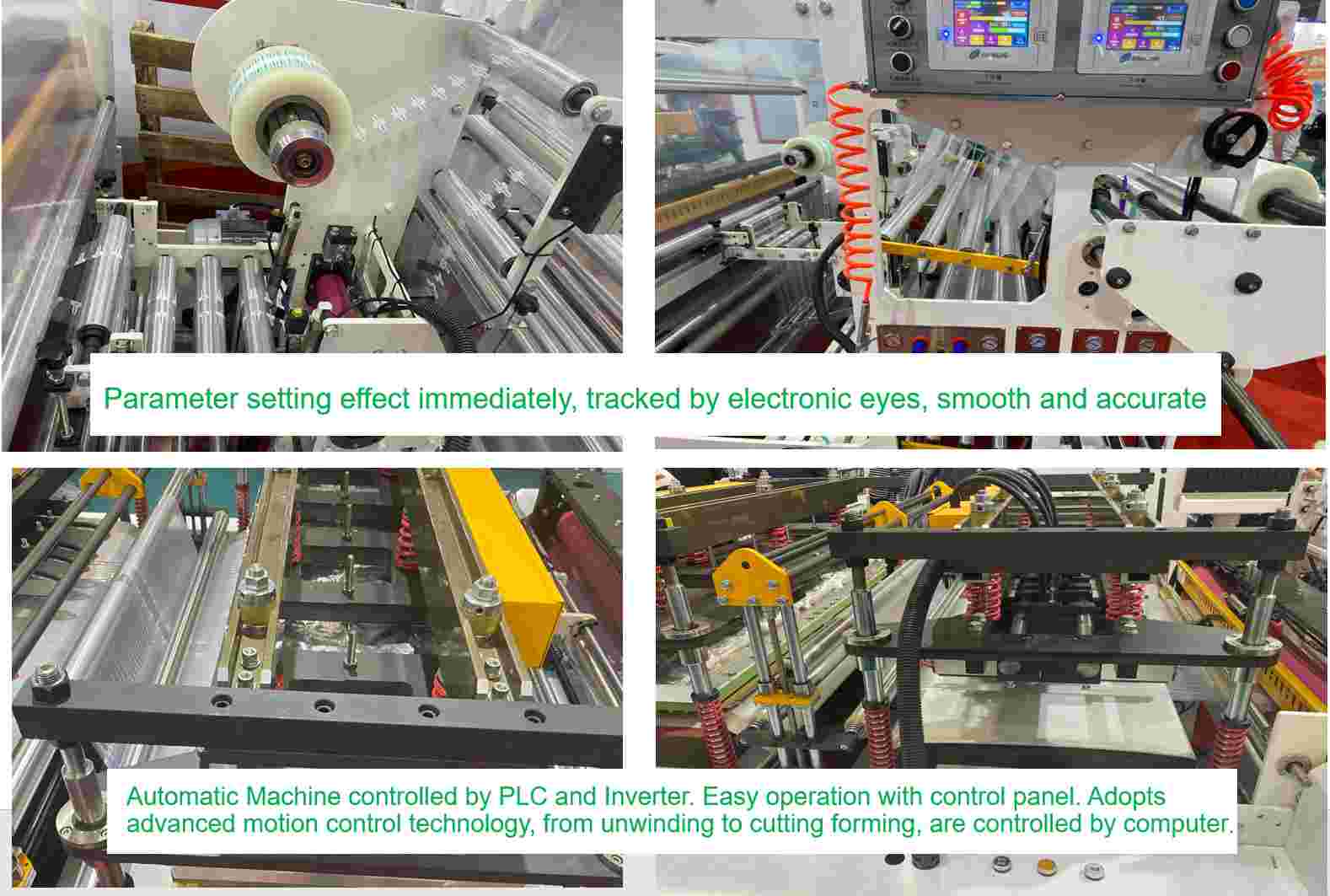

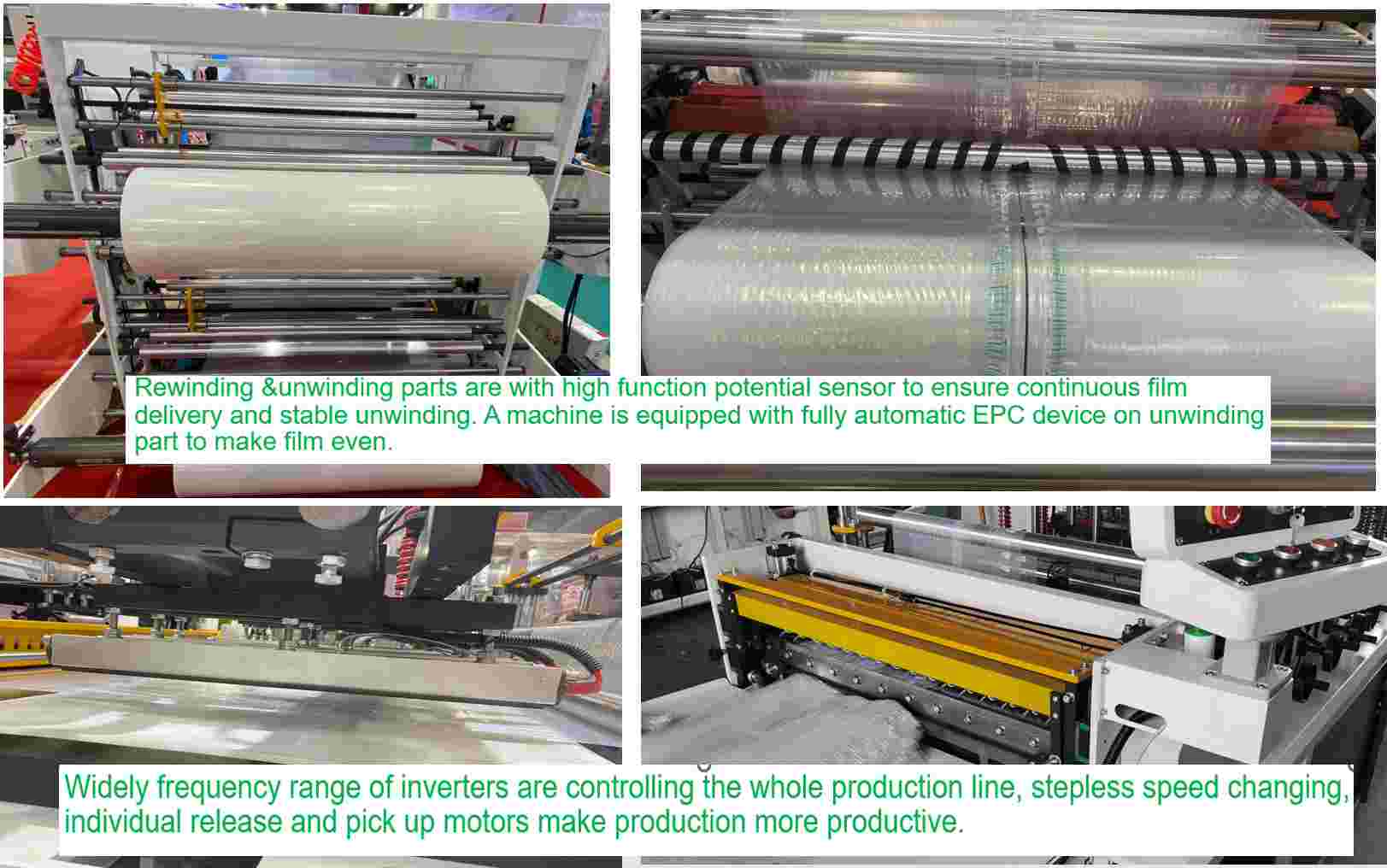

1,Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and pick up motors make production more productive.

2, Easy to load and unload products with air shafts in the rewinding and unwinding parts

3, A,B machines have functions like auto homing, auto alarming and auto stop etc.

4, A machine is equipped with fully automatic EPC device on unwinding part to make film even.

5, Rewinding &unwinding parts are with high function potential sensor to ensure continuous film delivery and stable unwinding.

6, The main machine adopts inter-grating device of motor reducer brake all-in-one, without belt chains or noise. Its stability &precision are much higher.

7, B machine’s unwinding is with photo-eye EPC to make film more flat and tighter.

8, Combined A+B machine is optional, and increase productivity.

9. Not the longest history machine but the most upgraded model in China. More and more famous packaging companies upgrade air column cushion bag production line with our machines.

Application

Our Factory

Your Reliable Air Cushioning bag making machine Supplier in China