Air column cushion roll making machine

Machine Introduction

Air Filled Bags for Packaging machine, Inflatable Packaging rolls making machine, Air Packing Bags conversion line, Inflatable Packaging Bags production line, Inflatable Bottle Packaging processing line, Air Shock Packaging bag making machine.

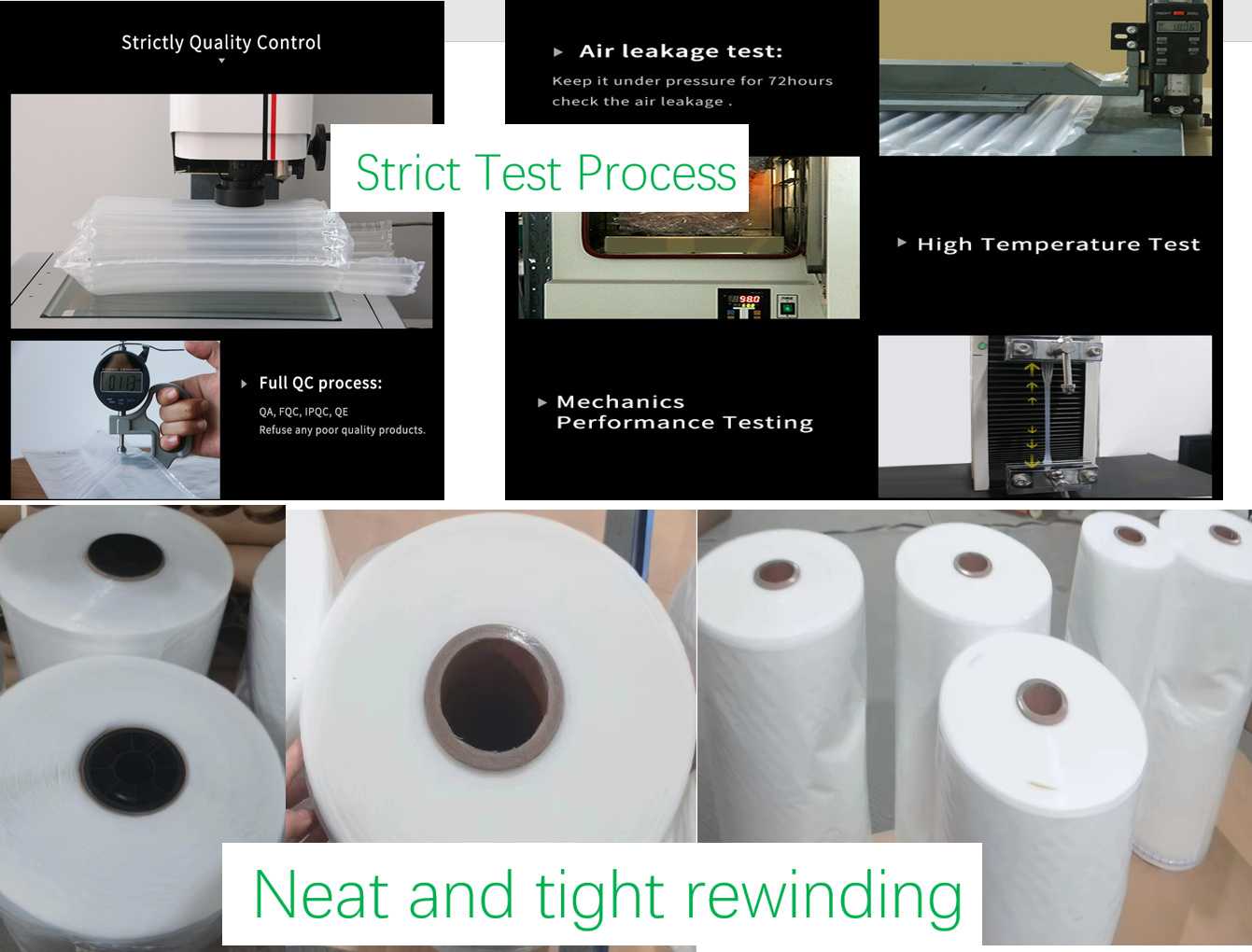

Air column bag making machine is a mechanical designed production line with all the advanced technology to make all kinds of airbag, cushioning bag, filling bag, paper airbag by PE Co-extruded film. Inflatable air column packing is made by LDPE+15%PA (nylon), it has a very good shockproof effect after inflation, which can protect fragile products without damage well during transportation.The products are low cost, saving space, re-cycling, easy packing, labor saving, and long time airtight for stock and transportation. Widely used in the packaging like small household appliances, computer communication and electronic consumables, logistics and transportation, lamps and fragile high-end consumer goods, business gifts, automotive electronics and electrical products. Electronic product packaging; alcohol packaging; green environmental protection materials; buffer packaging; home appliance packaging; alcohol anti-counterfeiting packaging; computer packaging; new packaging materials; instrumentation; precision instrument packaging products. Widely used in toner cartridges, all lamps, GPS, computers, electronics, printing supplies: (ink cartridges, toner cartridges, etc.); electronic products and other products of the inner packaging, can be used as a filler, play a role in moisture, water, and earthquake resistance.

Advantages

1,Simple linear type structure, easy in installation and operation.

2, Adopts advanced brand components like the pneumatic parts, electric system and operation parts. All the other machine parts are purchased from the best machine supplier chain area in China, which make the whole machine more stable than others. Almost zero after-sales needed from our clients.

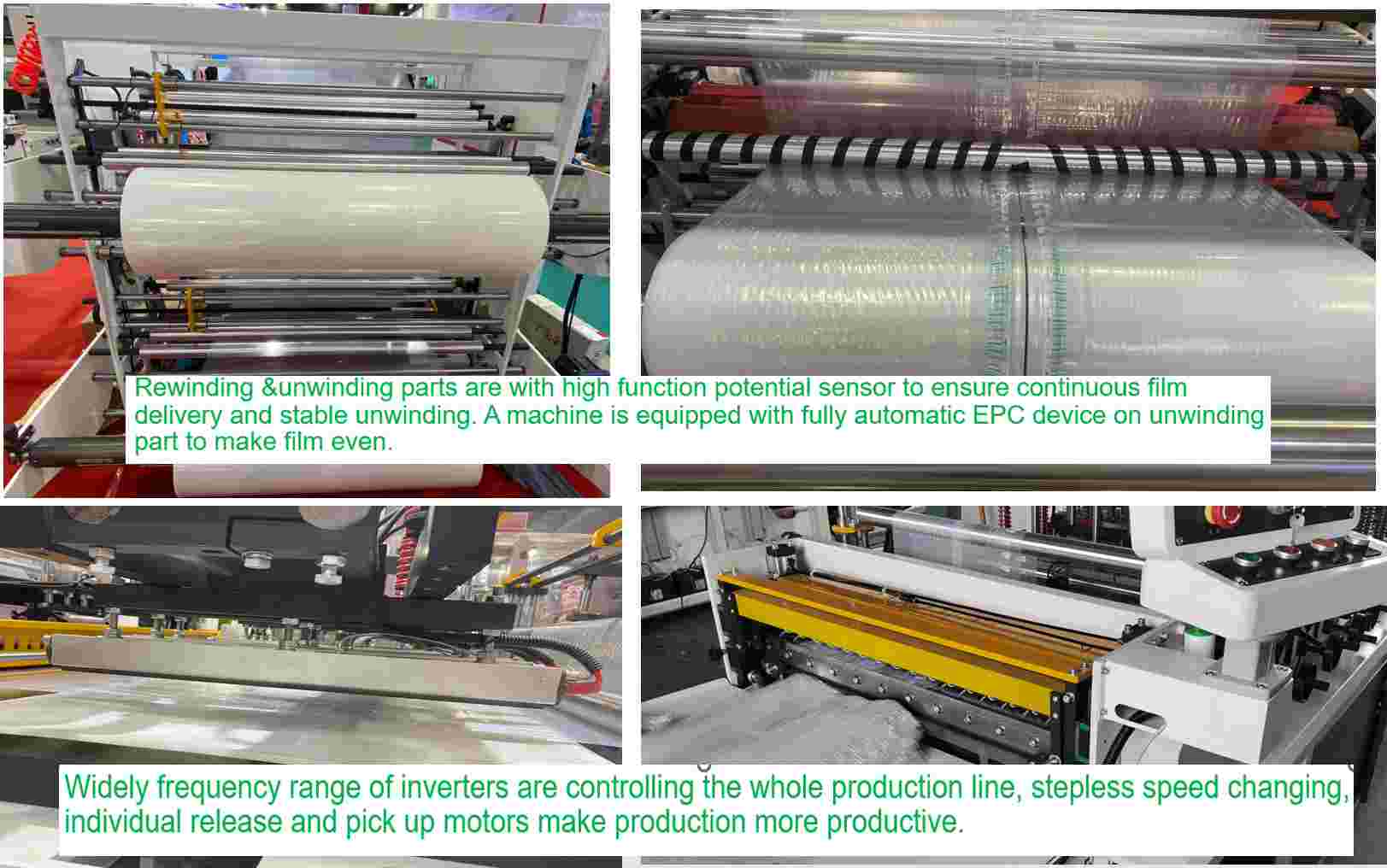

3, Running in a high automatization and intellectualization way. We are the unique supplier of the machine with Automatic rewinding in China.

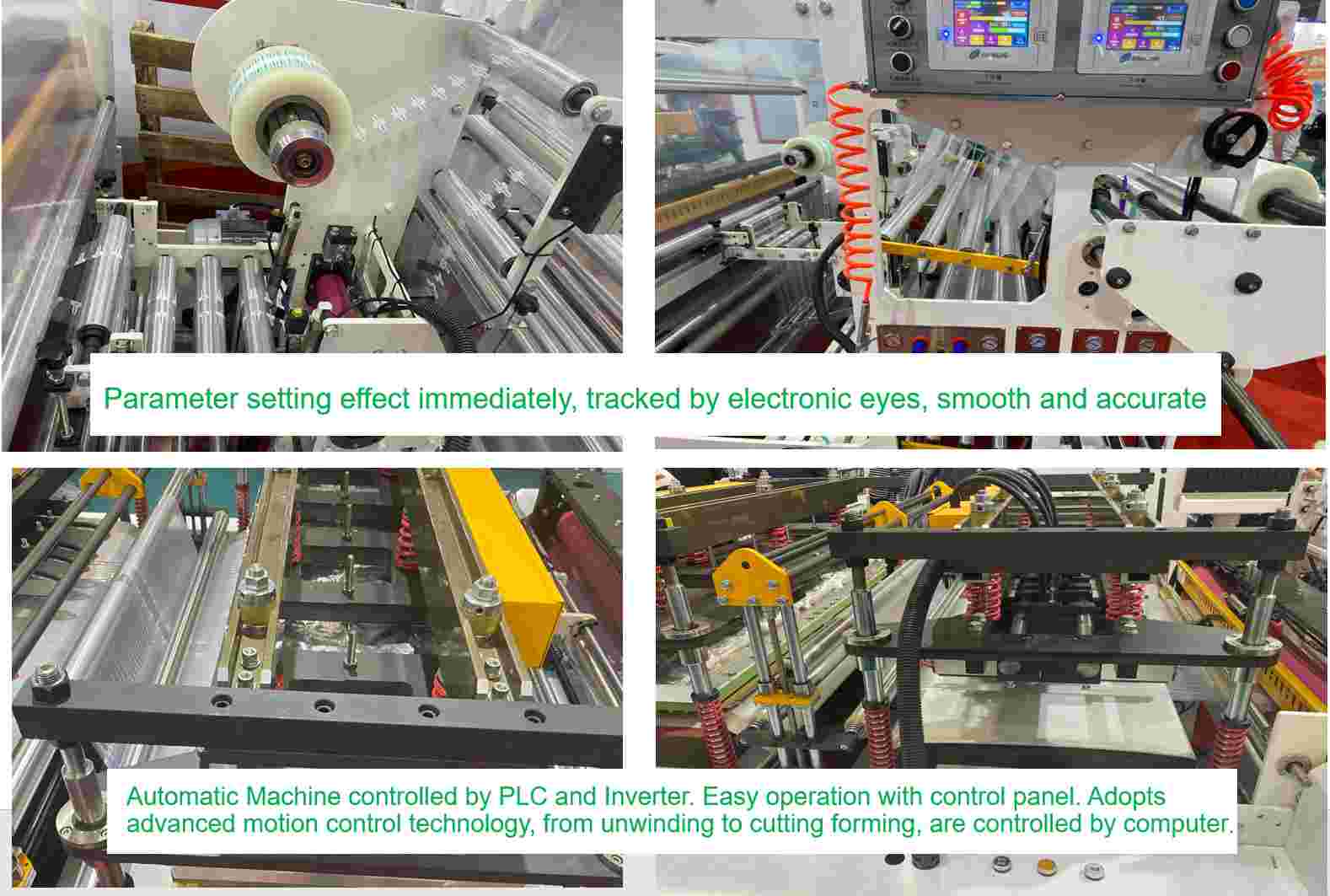

4, Air Column Bag rolls Making machine, Inflatable Bottle Protector making machine adopts advanced motion control technology, from unwinding to cutting forming, are controlled by computer

5, Automatic wine Bottle Protector making machine, Inflatable Wine Bottle Protector making machine controlled by PLC and Inverter. Easy operation with control panel.

6, Parameter setting effect immediately, tracked by electronic eyes, smooth and accurate.

7, Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release and pick up motors make production more productive.

Application& Related items

Our Factory

We are leading manufacturer of Inflatable Air Packaging Bag making machine, Air Column Packing rolls making machine, Air Cushion Bag production line, honeycomb mailer

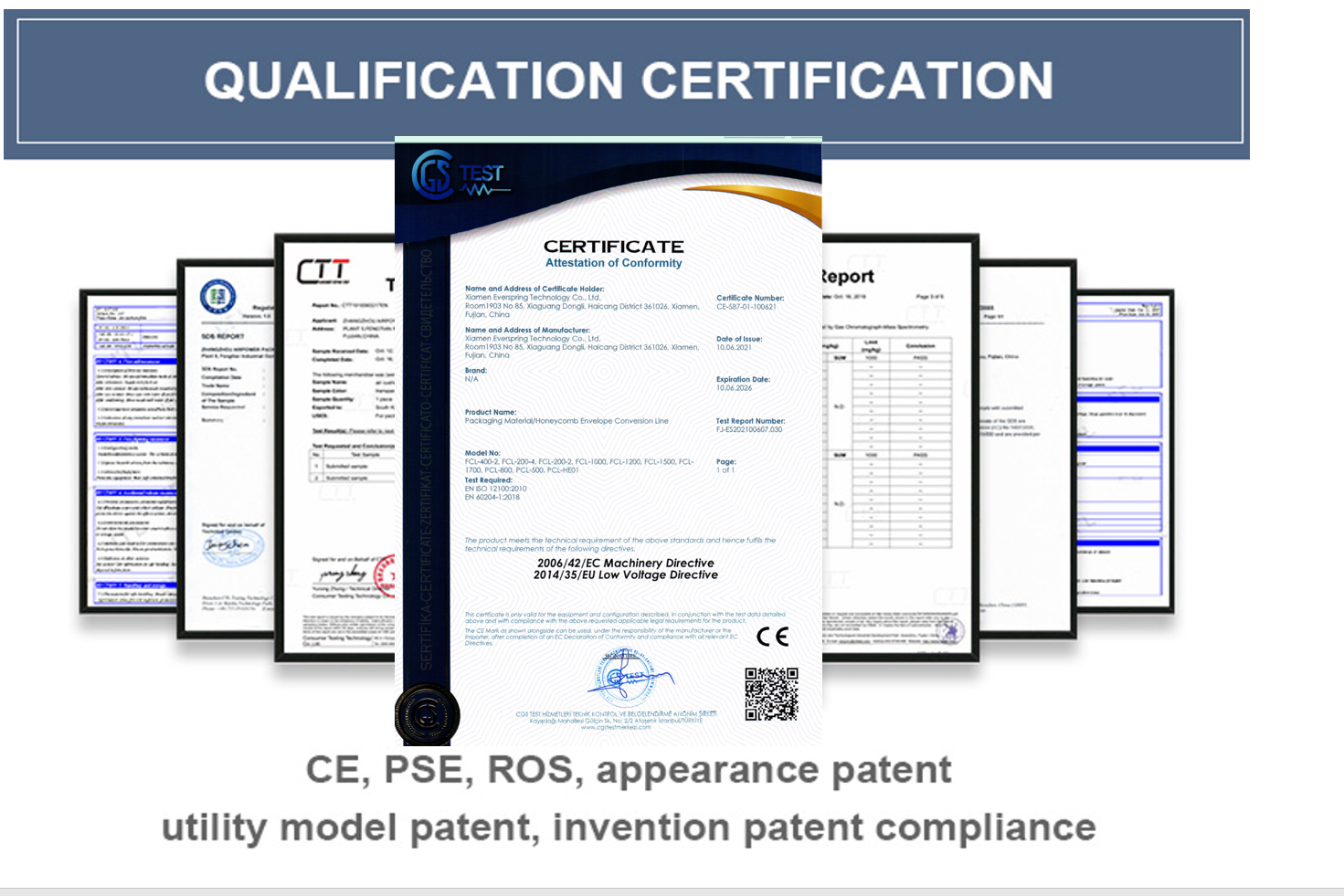

cerficicaiton